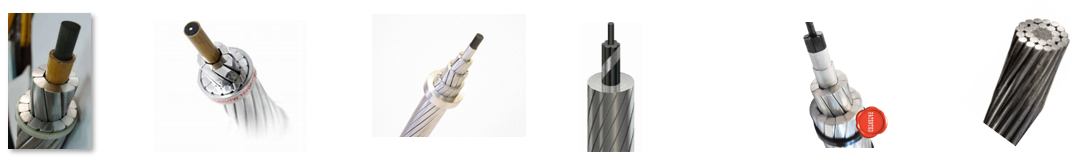

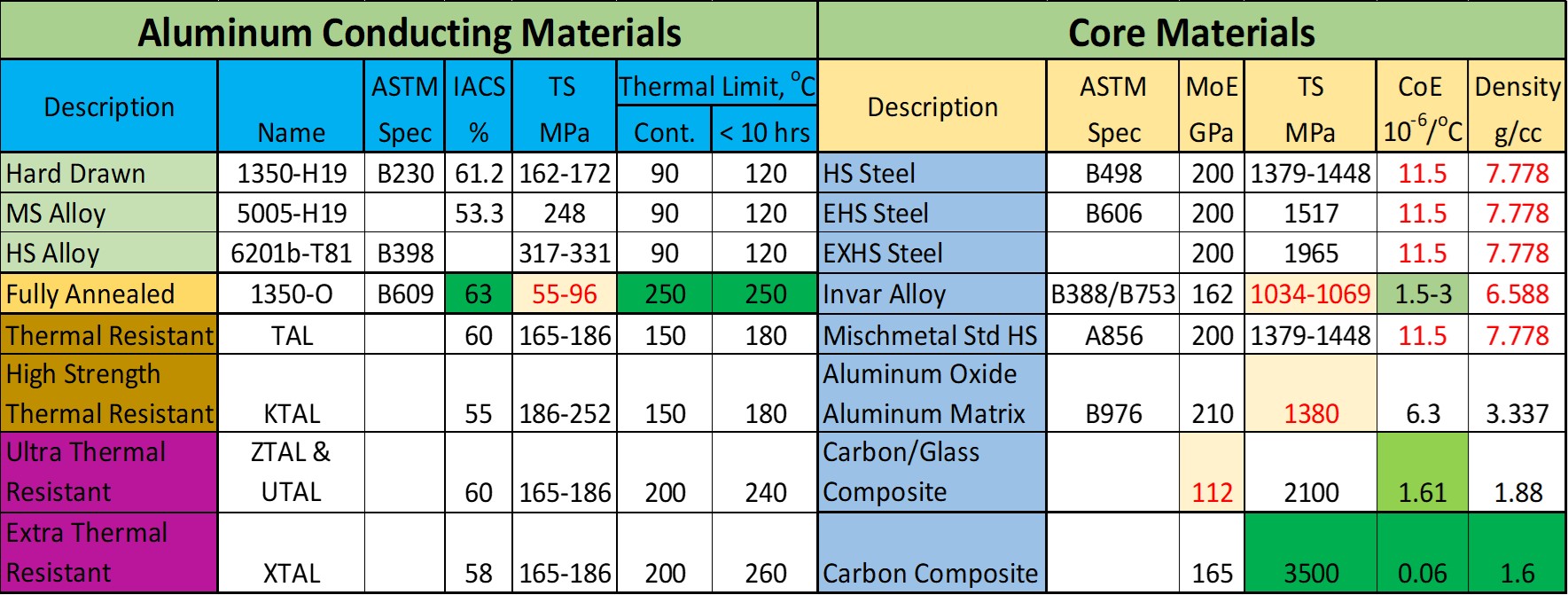

Conductor Constituents

Options for Aluminium (CONDUCTIVITY)

Options for Core (STRENGTH)

ACSR – A Century Old Technology

ACSR Deficiency:Strength、Thermal Sag、Ampacity、Line Loss

|

一、Steel as Strength Member,Limited Strength Need Hard Aluminum:Resistance High, Temp Limited 二、Self Weight,Thermal Sag Steel High CTE,Conductor Serious Thermal Sag 三、Limited Ampacity,High Line Loss Temp Limited(<90℃) High Resistance; Large Line Loss 四、Longevity Subjected to Environmental Degradation |

|

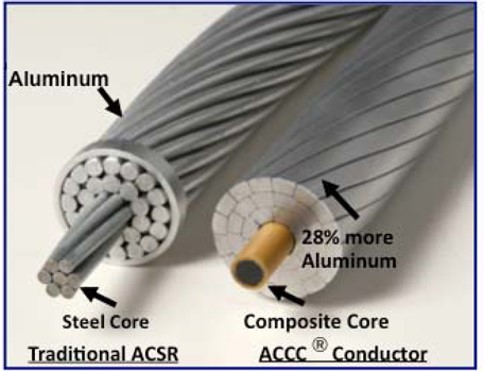

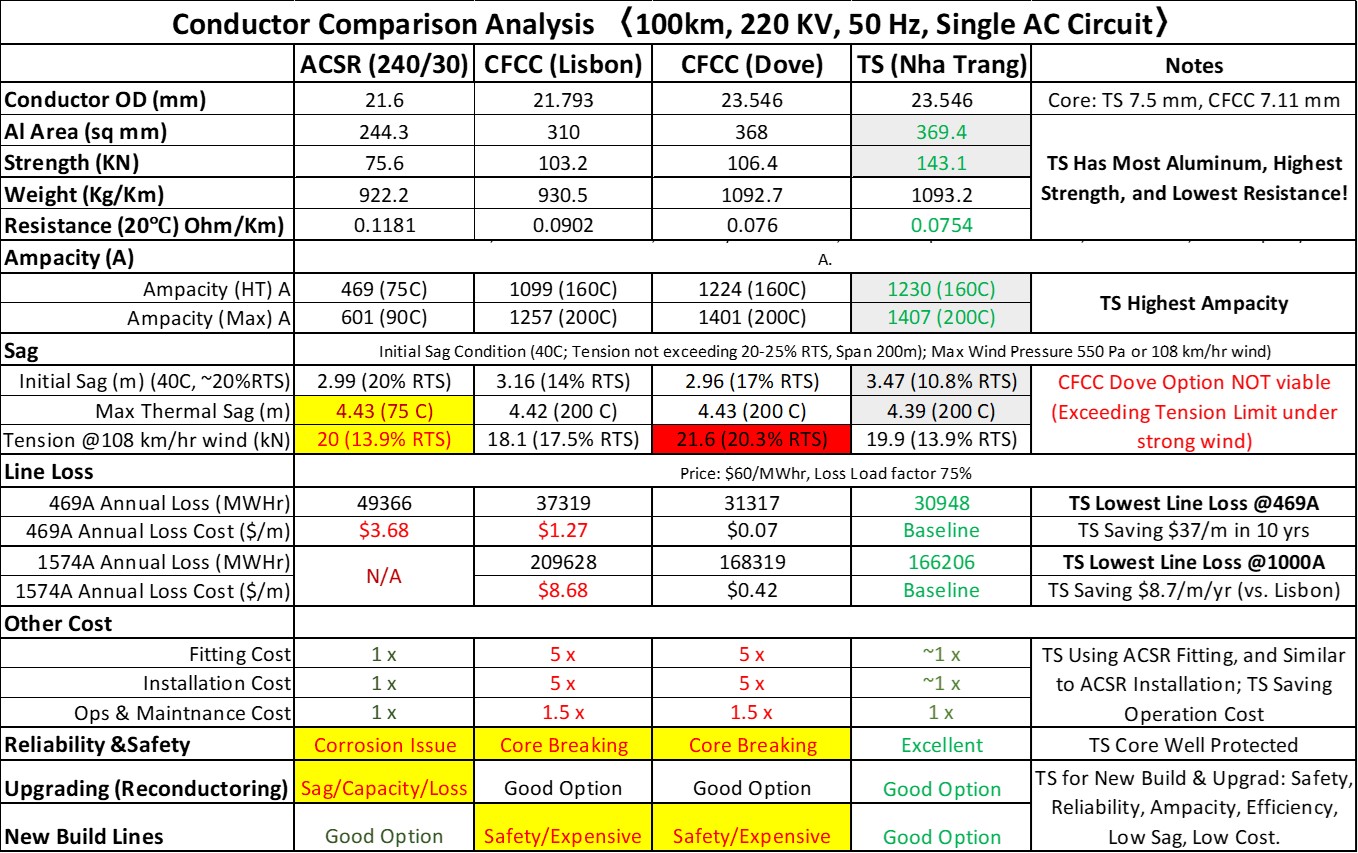

Conductor Example: ACSR vs CFCC (capacity、loss、sag)

|

ACSR 100+ yrs Technology • Broadly Used (>95% • Safe & Reliable • Grid 1st Choice • Large Sag, Temp limited to <90 C |

|

CFCC 90s, Japanese Technology & Goldsworthy 2002 ACCC from CTC Cable 2005 Deployment Emergence of ACCC like Chinese products (2010) Other Variants - Mercury, Nexans, Southwire, De Angeli |

|

CFCC Advantage (High Temp, Low Sag, High Ampacity, High Efficiency) • 2x Capacity • Line Loss Reduced by 30% • Same Size Conductor: More Aluminum |

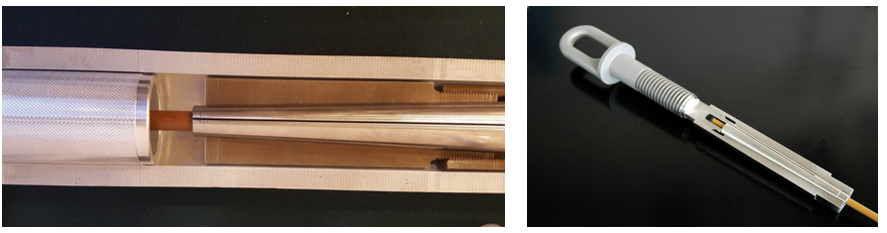

CFCC Special Fitting、Core Breaking

一、Special Fitting (High Cost: 5ⅹ、Training)

二、Vulnerability to Bending & Compression (especially Sharp Angle Bending)

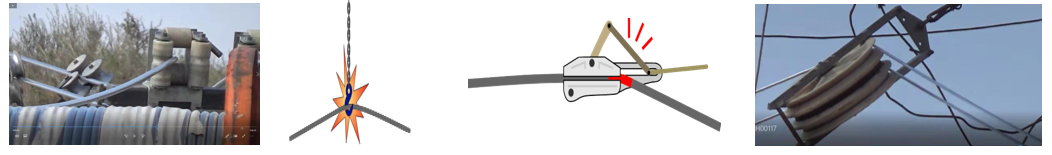

Failed ‘Composite’ Concepts to Replace ACSR

|

MFG: Product: |

CTC & Chinese ACCC |

Mercury HVCRC |

Nexans Lo-Sag |

CFCC/C7 Southwire |

De Angeli CFCC/C |

3M ACCR |

|

Flaws:

|

|

|

|

|

|

|

|

All CFCC Composite Core Options Are: Fragile and Vulnerable Due to Environmental Degradation and Bending Failures Costly, Unreliable, and Incompatible with Standard Industry Work Practices Limited in Field Applications - Significant Ice Sag, No Distribution Application |

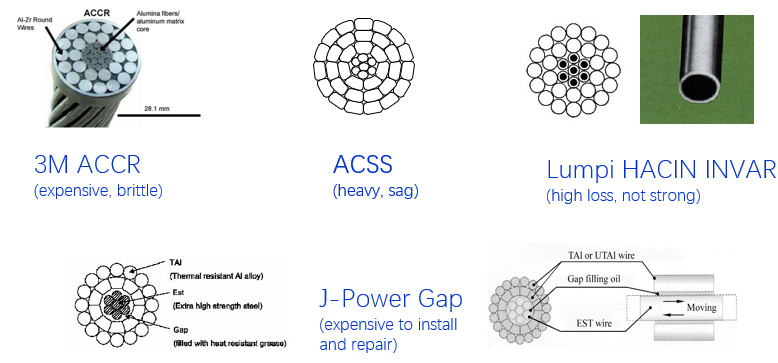

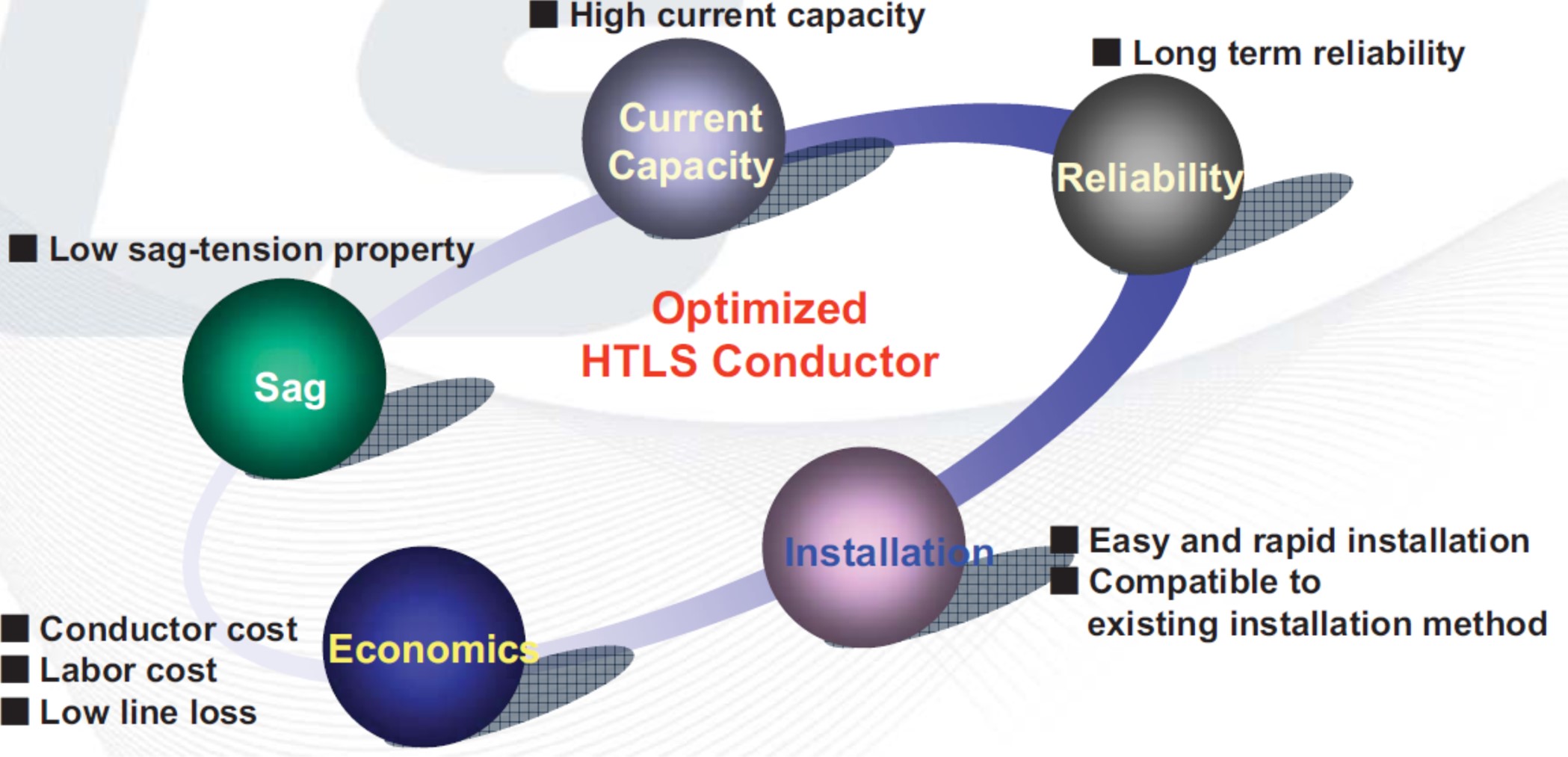

Other HTLS Conductor Examples: ACCR, ACSS, INVAR, GAP Options

Desired Attributes for Conductors

No Conductor Meets All the Five Requirements!

CFCC Issues (Safety、Longevity、Cost、Ice Sag)

A、The Glass Layer in Core (Preventing Galvanic Corrosion)

Thermal RESIDUAL Stresses,

I. CORE Strength Degradation over time (Glass Layer under Tension, Stress Corrosion Fatigue)

II. Carbon Core under Compression, more Vulnerable to Bending Failure

Low Modulus in Core and Conductor,

I. Excessive Sag in Large Ice Load

II. Excessive Sag with Larger and Heavier Conductor, and in Long Span

B、Safety Suspect (Vulnerable to Bending Break); Expensive Fitting and Installation

- Vulnerable to Axial Compression (Bending Damage in Manufacturing, Storage & Installation)

- Undetectable Bending Breakage to core; Expensive Installation

- Radial Compression Damage, Slippery Core; Wire Edge Grinding into Core; Expensive Special Fitting

C、Longevity Suspect (Subject to Environmental Degradation)

- Core Exposed to Environment (Gaps in Aluminum strands), Longevity Impact

- Air (Resin Thermal Oxidation), Moisture (Hydrolysis), UV and Ozone (Resin Degradation), etc.

- Tension and High Temp Operation Exasperate the Core Degradation

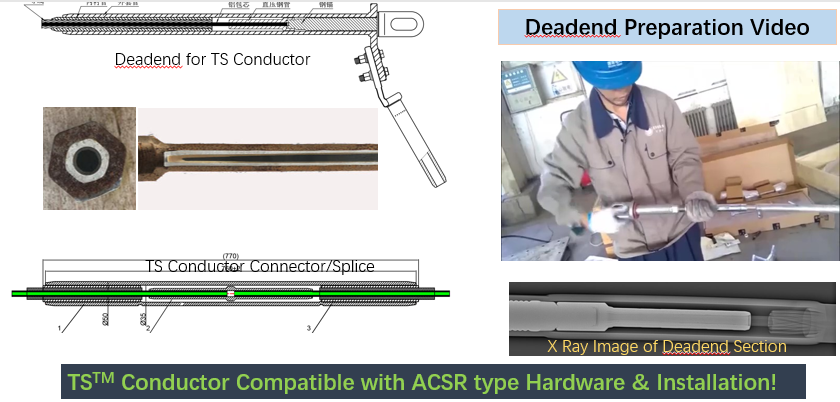

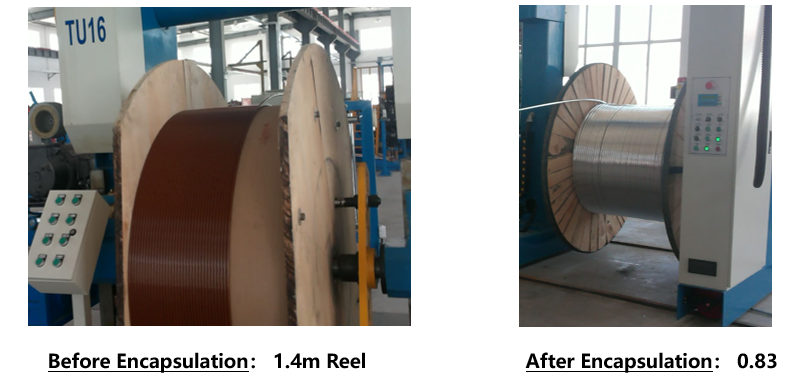

TSTM , the Enabling Conductor Technology

一、Desired Stress Condition in Core, via Aluminum Encapsulation

- Guaranteed Reliability: Eliminated sharp angle occurrence; Improved resistance to bending damage.

- Guaranteed Longevity: Shielded composite core from environment.

- Reduced Project Cost: Encapsulated core is fully compatible with ACSR type hardware and easy to install.

- Enhanced Performance: More Aluminum; Further improved Ampacity, energy Efficiency, conductor Strength and Modulus. Also Suitable for heavy ice and ultralong span applications

二、Patented Technology

- PATENTS Granted in US & China; Pending in Vietnam, India, Indonesia, Europe, Africa etc.

- TSTM, The Enabling Technology, addressed all remaining issues of CFCC conductors (Safety & Reliability, Longevity, Compatibility, Cost, and Performance)

- DOES NOT INFRINGE ANY Existing Patent (Core, Conductor or Hardware)

|

TSTM Core Robust against Mishandling (sharp angle) |

CFCC Sharp Bending Failure |

|

|

|

TSTM Conductor Offers Superior Safety & Reliability to Transmission Grid! |

CFCC Small Radius Failure |

|

Detectable During: |

TSTM Conductor Offers Superior Safety & Reliability to Transmission Grid!

TSTM Conductor Leverages Conventional Hardware and Installation Tools & Methodology

Enhanced Bending Ability (w/ TS Technology)

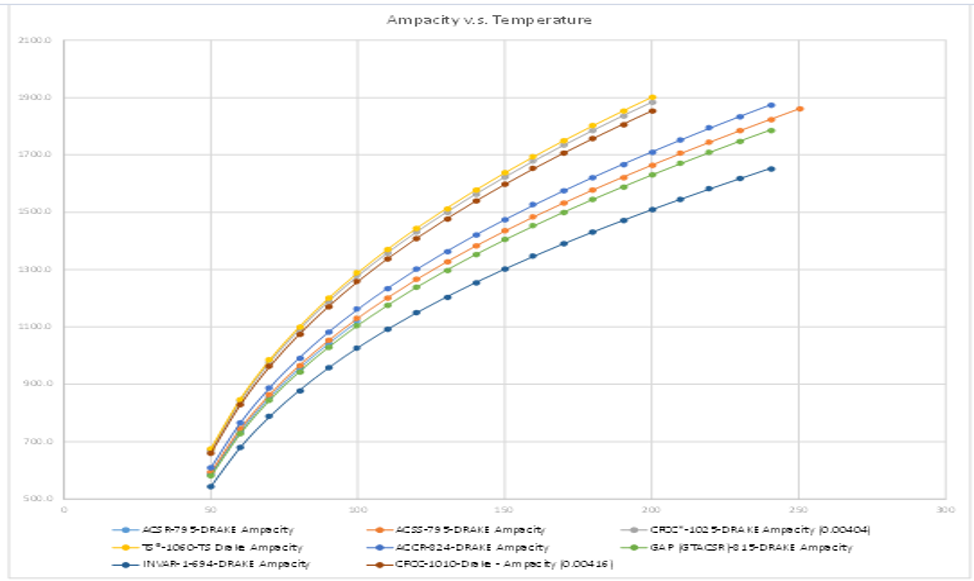

Best Ampacity (Drake Size Conductor Options)

TSTM Technology, The Conductor For Any Grid

TS CONDUCTOR FIELD APPLICATIONS

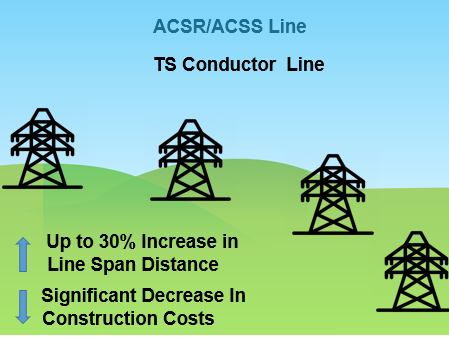

Total Solution (TS) Conductor’s increased capacity and lighter weight allows utilities to replace ACSR on existing T&D infrastructure without the need to retrofit towers or build new structures.

TS Conductor’s superior performance is ideal for new build applications, allowing increased span distance between towers or poles.

Ideal Applications for TS Conductor:

- Transmission

- Distribution

- New Line or Tower Builds

- Reconducting

Optimizes Your Competitive Position By Adding Capacity and Controlling Line Loss to Reduce Infrastructure Costs & Minimize Environmental Impacts

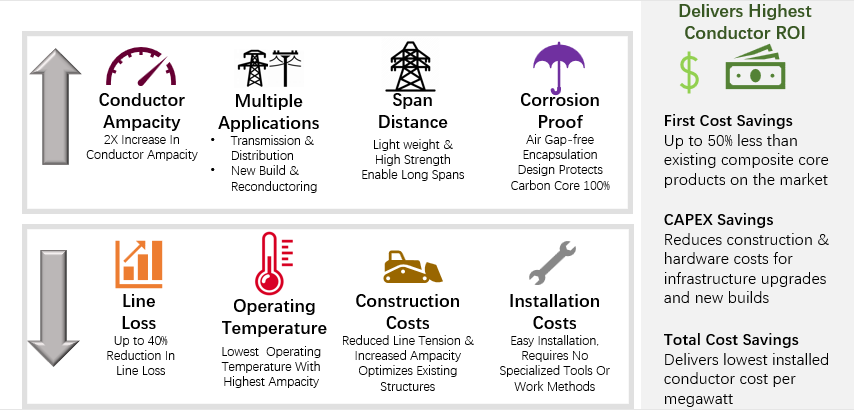

REDUCE COSTS, INCREASE CAPACITY & EFFICIENCIES

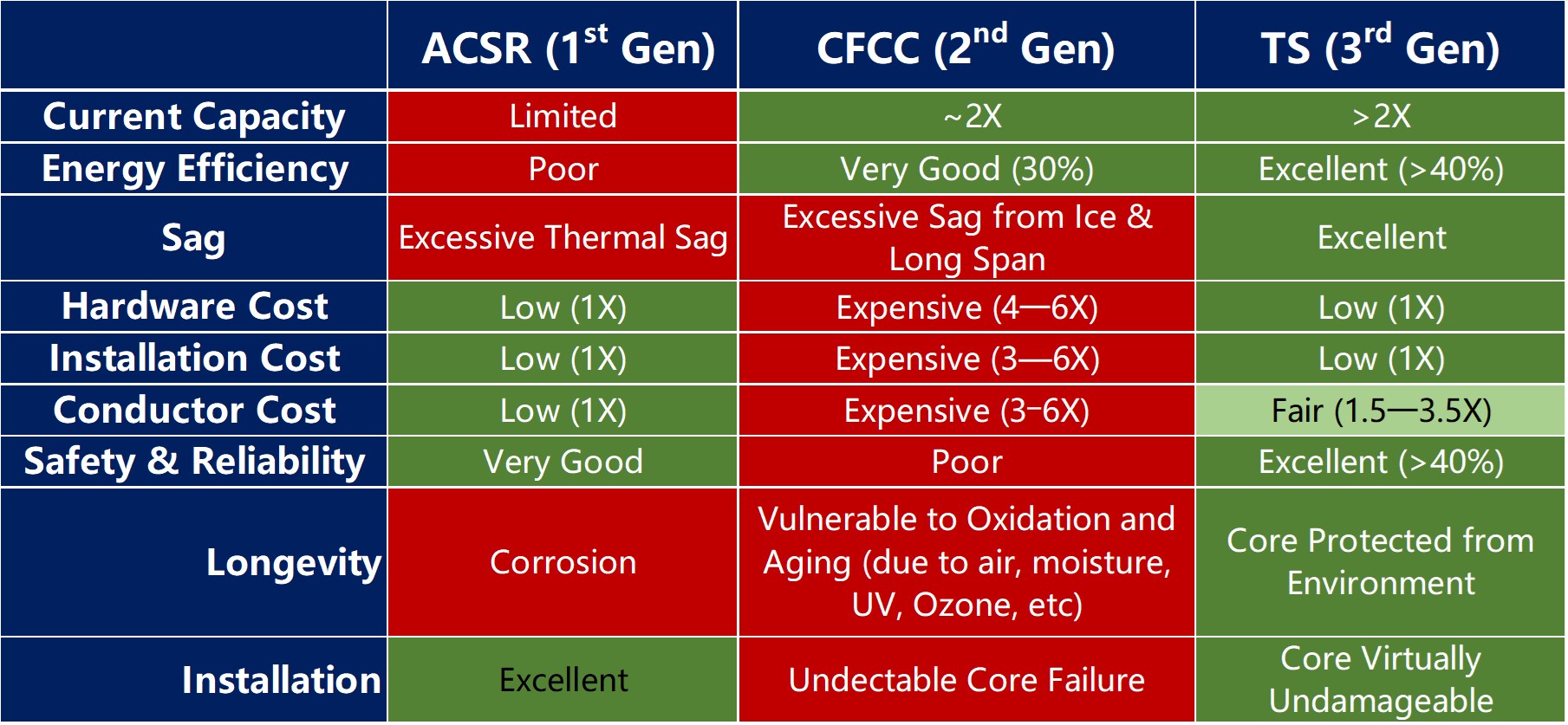

TSTM Conductor Comparison (HTLS)

|

TSTM Offers

Optimal for Both Reconductoring and New Build!!

|

|

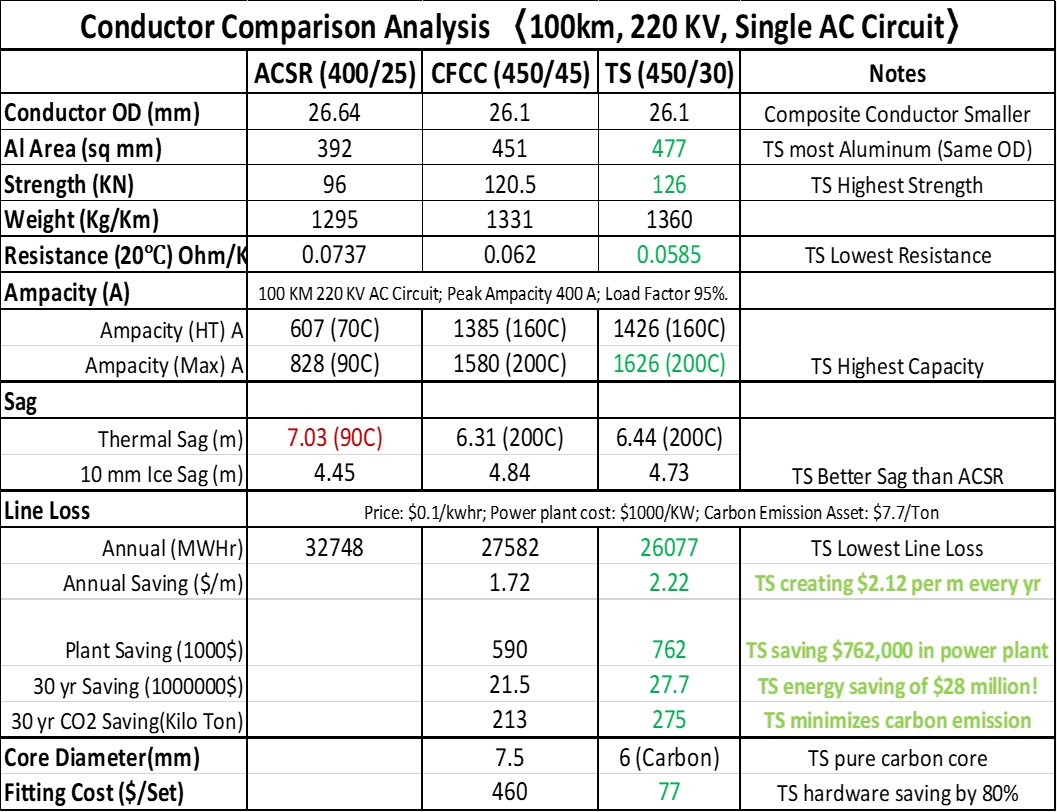

TSTM Conductor: GREAT VALUE

|

TS Conductor Best Performance

TS Conductor Best Value

TS Conductor Lower Cost (vs. CFCC)

|

|

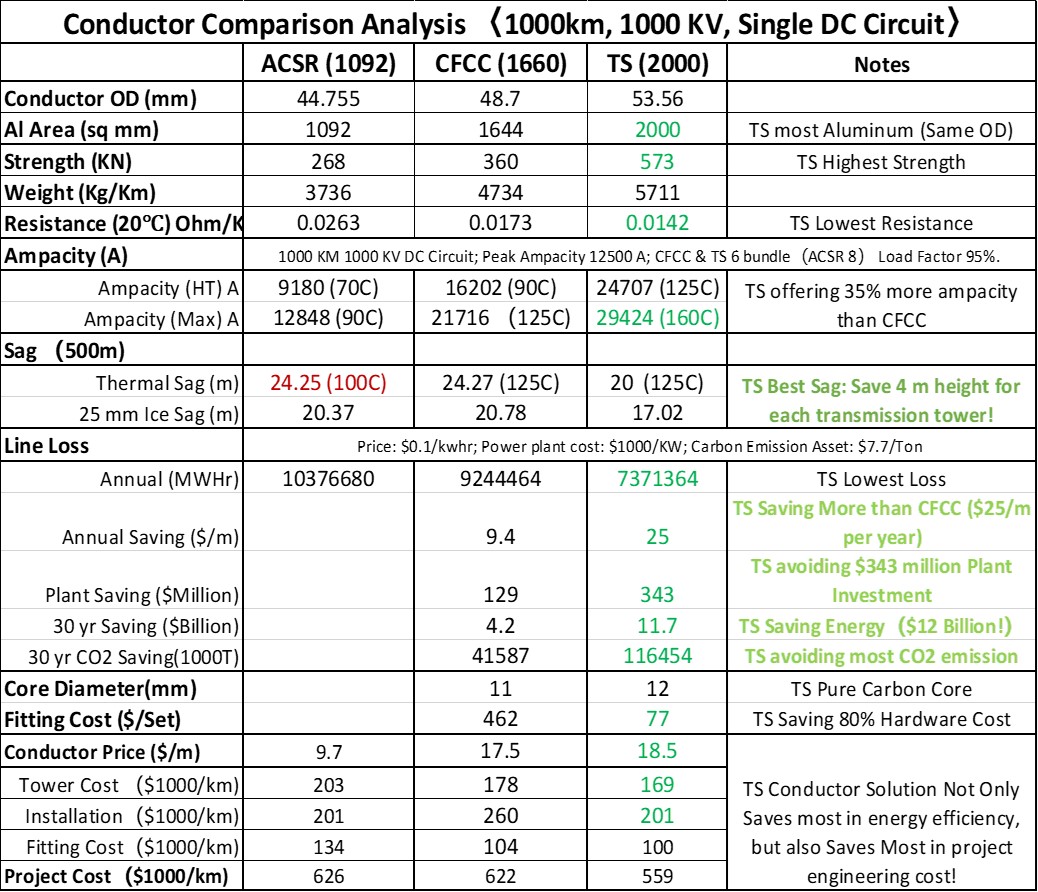

TSTM Best Value in Performance & Cost (UHV DC)

|

TS Conductor Best Performance

TS Conductor Best Value

TS Solution: Lowest Project Cost

|

|

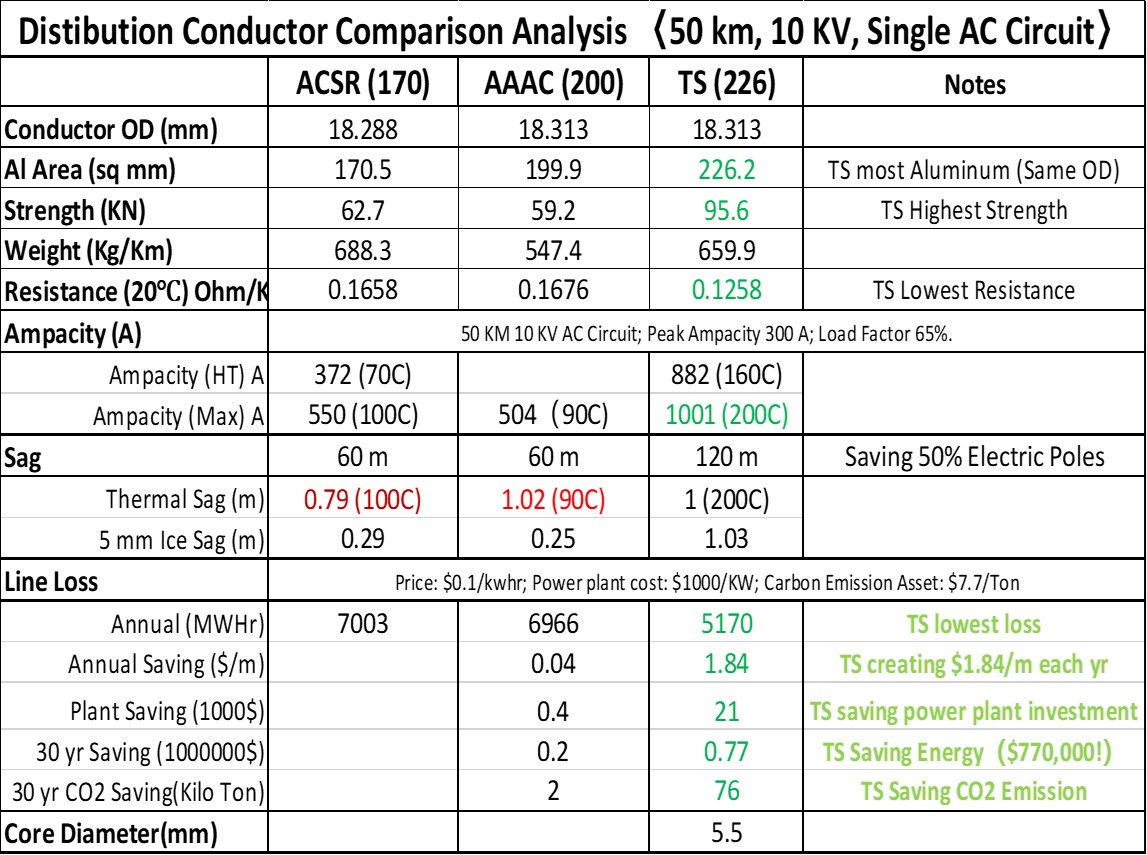

TSTM Conductor Superiority in Distribution

|

TS Conductor Best Performance Highest Capacity (~ 237%ACSR) Lowest Resistance Highest Strength Excellent Sag Good Option for Lightening Strike TS Conductor Best Value Lowest Loss ($1.84 per m each yr) Reducing Power Plant Cost ($0.2 m) Energy Saving (30 yr: $770K) CO2 Emission Saving (30yr: 76000 T) Carbon Asset: $354K TS Solution Lower Project Cost Saving 50% Poles and associated fittings, land and installation costs |

|

TS Passed China EPRI Type Testing (2015 & 2016)

TSTM Proven Product Adoption

|

State Grid of China

Most recent TS Conductor T&D reconductoring project:

Tested by Chinese EPRI, Vetted By State Grid and Endorsed by China Electric Council Patents granted in U.S and China. Comprehensive protection for TS Conductor technology in over 50 countries. |

|

SUSTAINABLE SOLUTION

TS Conductor’s safe, cost-effective solution significantly improves ampacity, increases reliability and promotes global sustainability by optimizing the power grid. TS Conductor helps reduce the carbon footprint by significantly decreasing the need for additional power generation, maximizing renewable energy interconnections, and increasing capacity within the utility’s existing infrastructure.

TS Conductor technology could reduce the carbon footprint by approximately:

|

550 Giga Watts of Electricity |

650 Million Barrels of Oil |

80 Million in CO2 Auto Emissions |

1.68 Million Acres of Forest |

TSTM Conductor Is Ready!

It Solved All the Shortcomings of CFCC Conductors

- REIABILITY (Core and Conductor Manufacturing, Storage, Installation)

- Longevity (Not Subjected to Environmental Degradation)

- Low Cost (Conventional Fitting & Installation)

- Better Performance (Higher ampacity, Better efficiency, Lower Sag including ice and long span applications)