Energy Management for Smart Factories

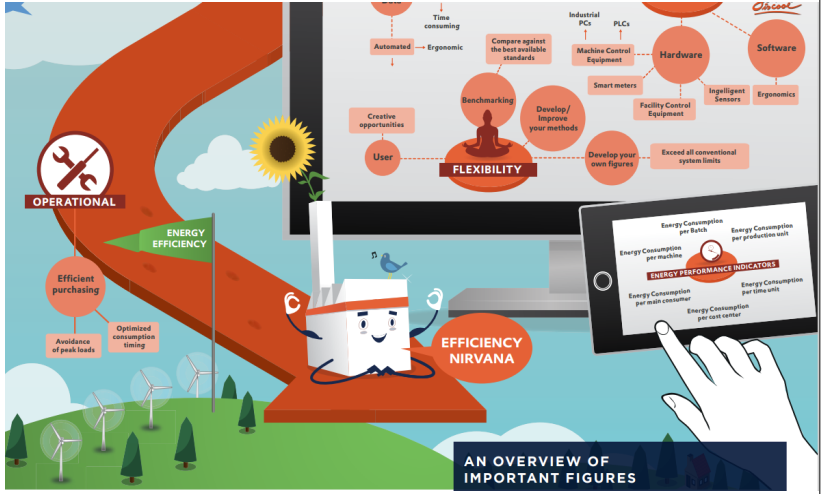

Energy Management System for Factory

Importance of Energy Management

|

Energy costs make up a significant portion of a plant's Energy costs represent a significant portion of our operating expenses. • Effective energy management helps reduce costs and improves our factory's overall competitiveness. • It also contributes to environmental sustainability and corporate social responsibility |

|

Key Objectives of Energy Management

|

Energy Efficiency: We aim to use energy more efficiently to achieve the same production output or better with reduced energy consumption. Demand Management: By monitoring peak demand and strategically scheduling operations, we can avoid costly energy spikes. Renewable Energy Integration: Exploring and implementing renewable energy sources can help offset our reliance on conventional energy and reduce greenhouse gas emissions.

|

|

Energy Saving Strategies

|

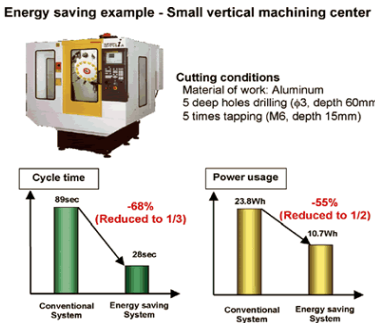

Upgraded Equipment: Replace outdated machinery with energy-efficient models that have better performance and reduced energy consumption. ▪ Lighting Optimization: Use energy-efficient LED lighting and implement motion sensors to avoid unnecessary energy wastage. ▪ HVAC Management: Optimize heating, ventilation, and air conditioning systems to ensure they operate at peak efficiency. ▪ Employee Awareness: Educate and involve employees in energy-saving practices to foster a culture of energy consciousness.

|

|

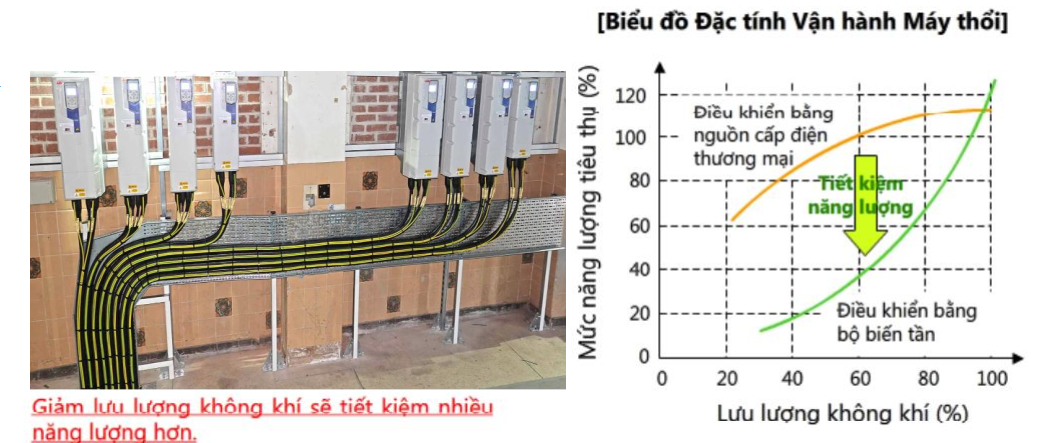

The application of the inverter is to save the power consumption of 3-phase electric motors

|

The main purpose of the inverter is to control the speed of the motor, because its ability to adjust the frequency will make the motor change speed. This is the initial requirement set for the inverter to be born. After the actual use process, when installing the inverter for the motor with some special applications, it was found that compared to the time when the inverter was not installed, the motor's power consumption decreased a lot from 20- 30%, sometime this application reduced up to 40-50%.on |

|

For example, a lathe that only needs a 3.7kW motor is enough to pull the turntable, but for some reason people install a motor up to 5.5kW. In this situation, if you install an inverter and slow down the speed of this motor, it will save a considerable amount of energy.

Peak Demand Management

schedules to avoid energy-intensive processes during those times.

from lower rates during off-peak hours.

Some actual statistics recorded:

capital investment while also reducing energy waste costs by 8% to 13%.

operators respond quickly to abnormalities.

exceeding the contracted energy capacity

|

|

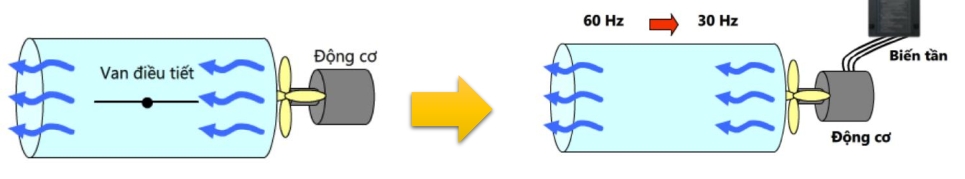

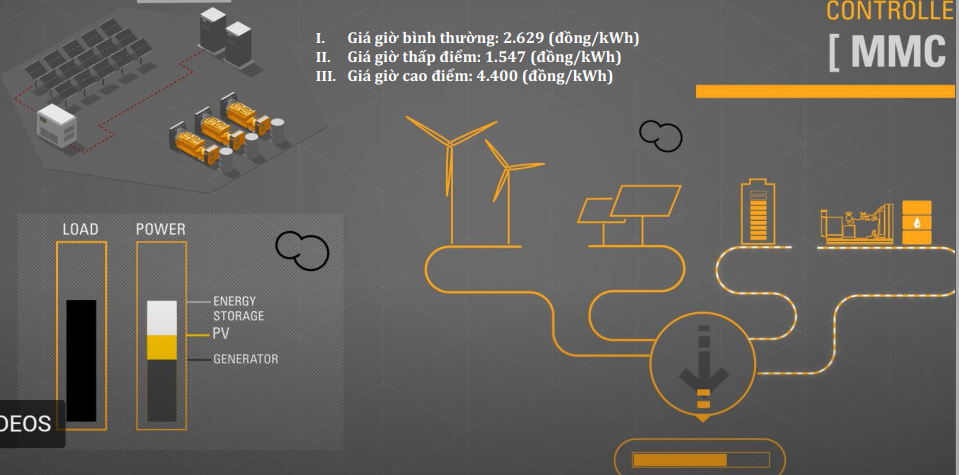

SMART GRID

I. Normal hours cost: 2,629 (VND/kWh)

II. Off-peak hour price: 1,547 (VND/kWh)

III. Peak hour price: 4,400 (VND/kWh)

Applications of inverters is to save power consumption of 3-phase electric motors.

|

For commercial premises such as offices and public buildings, inverters can be applied to the electric motors running the HVAC fans, chillers, pumps and cooling towers. For industrial and manufacturing premises inverters have been proved to successfully reduce energy and the associated costs for conveyors, compressors, cooling towers, mixers, pumps, fans, chillers, extruders… For warehousing and logistics sites inverters are successful at reducing energy usage on their large HVAC For quarries, metals and mines inverters can be used to help control crushers, pumps, extract fans, conveyors, hydraulic power packs, compressors. For leisure facilities, hotels and restaurants inverters have been proved to save energy on applications such as pumps, fans and HVAC |

|

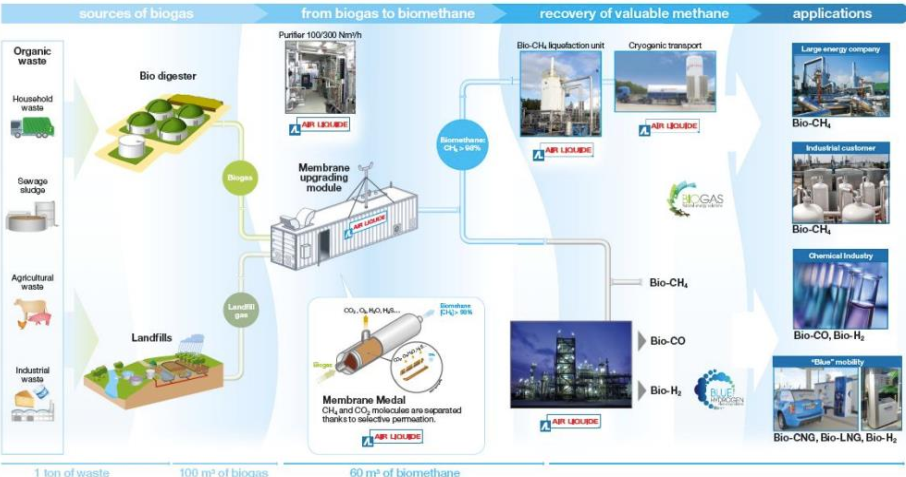

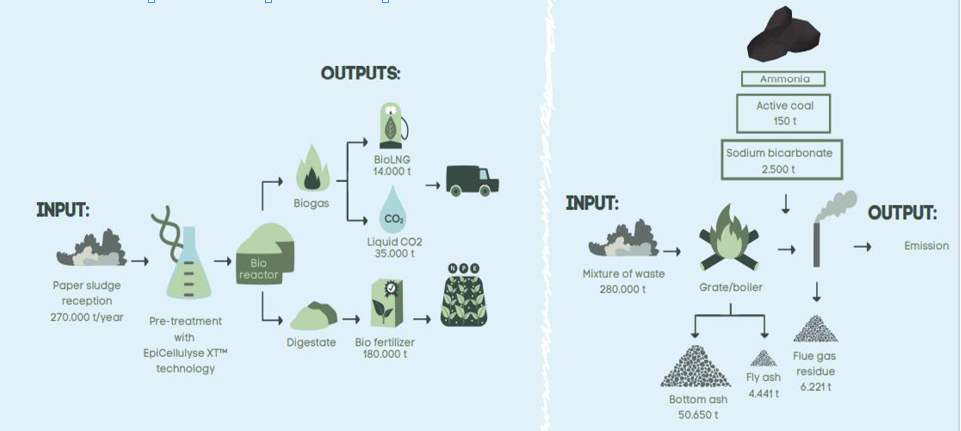

Bioenergy solutions

Applications of Biomass converted into Bio fuel & Bio Energy

| New Method | New method |

|

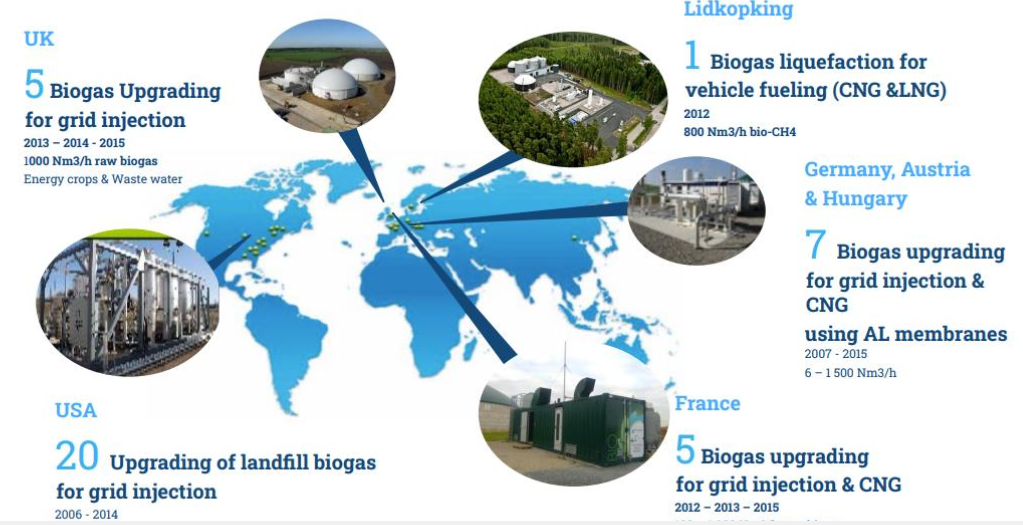

Biogas - Overview

| 15 years of experience in biogas upgradmg | 200,000 Air Liquide, world leader in biogas purification with a capacity of >200,000 m3/h | 1,000 to 3J500TW.1H Market potential |

More than 50 biogas units operating worldwide

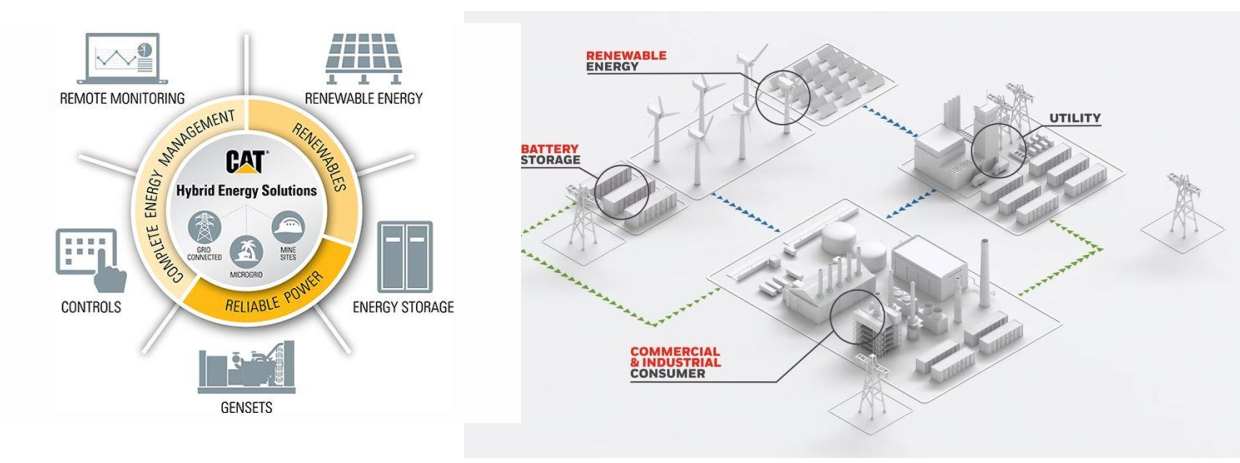

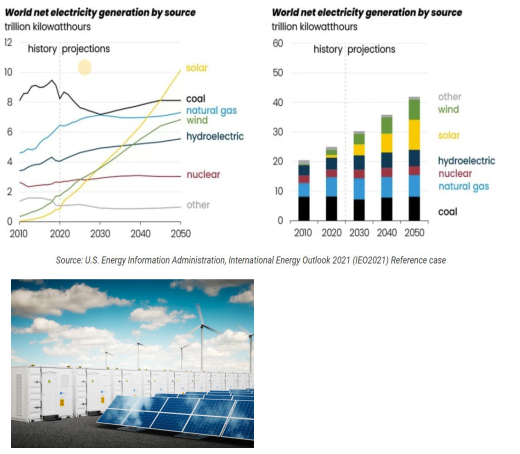

Renewable & Smart Energy Storage Solutions

Evaluate the feasibility of solar panels, wind turbines, or other renewable energy sources on-site.

Partner with renewable energy providers or invest in community solar initiatives.

Implement energy storage systems to store excess energy during low-demand periods and use it during peak hours.

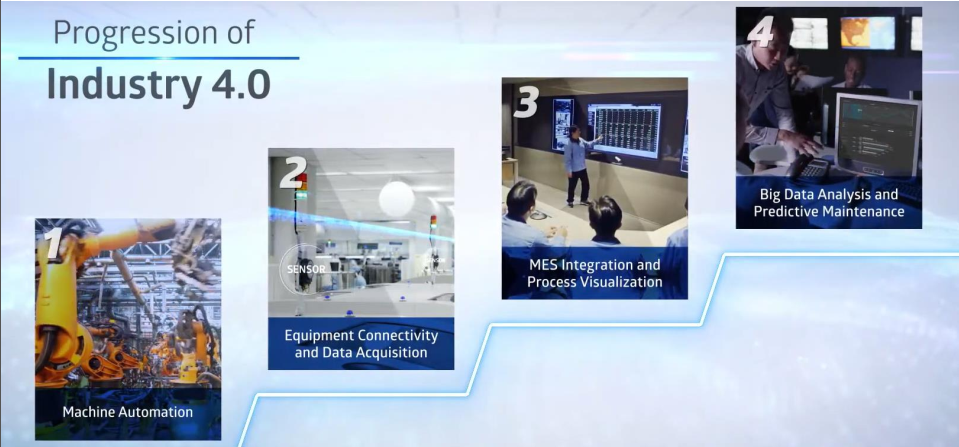

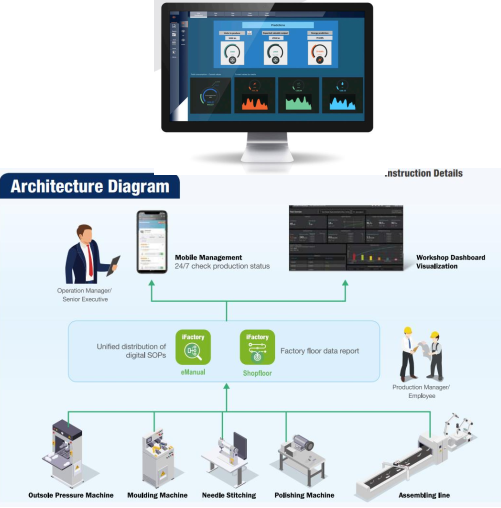

The 4.0 Industry Revolution

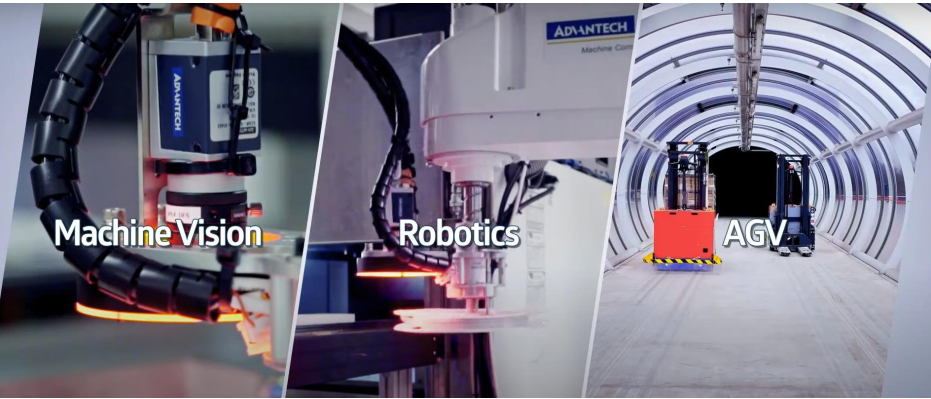

I. Machine Automation

Reduce the dependence on manpower and tighten-up production

II. Equipment Connectivity and Data Acquisition

IoT Sensor devices technologies

Data can be collected and transmitted in real time

II. MES Integration & Process Visualization

IV. Data analysis

Research Example: How much money can one LED light bulb make us?

• Minimize the energy consumption as much as possible

• Some Fabs or factory are 24/7 operations

• Minimizing the power consumption by any means is important.

Lighting is a large part of that. Additionally, environmental control via air conditioning systems is key the LED tubes are 120-160 lm/W

• Compared to a standard 1.2m (4ft) fluorescent tubes, LED tube save 185-200 kW-h of power per tube every year

• plus, they save an additional 75-80 kW-h of power in air conditioning costs $190 per tube over the 5 year warranty period!

| One 1.2m LED tube | Saving | Money Cost |

| Energy (Lighting) | 200 kW.h/Year | $20 |

| Air conditioner (Cooler) | 80 kW-h/Year | $8 |

| Down time | $10/Year | $10 |

| Total | $38 |

| Total Saving in 5 Years $190 | $190 |

Compared with standard 1.2m (4ft) fluorescent tubes, LED tubes save 185-200 kW-h of electricity per bulb per year plus, we save 75-80 kW-h more electricity in the cost of air conditioning. So Total Savings: $190 per bag during the 5-year warranty period!

Comparison table

| Description |

Fluorescent tubes 1m2 |

Led tube 1m2 |

| Power | 36W | 20W |

| Efficiency |

62lm/w |

120lm/w |

| Life time |

10,000h |

50,000h |

Global Founderies, Germany

Our customers report a modest size fab of 25,000 lights easily save annually more than $3,000,000 USD in maintenance, stocking, shutdowns and disposal charges. (Global Founderies, Germany) In 2021, our clients saved more than $7,500,000 USD in energy savings and more than 3X that much in maintenance and down time!

Conclude

Adopting an effective Energy

Management System for our factory is a strategic move that benefits both our business and the environment.

By optimizing energy usage, we can enhance our competitiveness, save costs, and demonstrate our commitment to sustainability.

Financial and Environmental Benefits

Reduced Energy Costs: By implementing energy-saving measures, we can expect significant cost savings over time.

Environmental Impact: Our commitment to energy management and renewable energy will reduce our carbon footprint, contributing to a cleaner environment.