The backdrop

Green hydrogen is part of the global response to keeptemperature increases from preindustrial levels below 2°C

Technip Energies at a glance

|

TE Euronext Paris listing ticker ADRs for US investors |

Headquarters in Paris Registered in The Netherlands |

60+ Years of operations Green |

|

€6.7B Full year 2021 adjusted revenue |

A leading engineering & technology company for the energy transition |

€16.4B Backlog at the end of March 2022 |

|

~15,000 Employees in 34 countries |

25+ Leading proprietary technologies |

450 projects under execution |

Four business lines

|

Gas & Low-carbon Energies |

Sustainable Fuels, Chemicals & Circularity |

Carbon-free Solutions |

T.EN X Consulting & Products |

• Increasing efforts to be market focused and customer-centric

• Reinforcing our positioning in technology, products and services

• Maintaining excellence in project execution

• Supporting ‘historical’ and new clients in their energy transition journey

• Leveraging our geographical proximity with clients and knowledge of local environments

Seizing energy transition opportunities

Shifting from geographical to market-focused

| THREE BUSINESS LINES DEDICATED TO MARKETS |

ONE CROSS-MARKETS BUSINESS LINE |

|

GAS AND LOW-CARBON ENERGY |

SUSTAINABLE FUELS, CHEMICALS & CIRCULARITY |

CARBON-FREE SOLUTIONS |

T.EN X CONSULTING & PRODUCTS |

|

•Liquefied natural gas (LNG) • Floating liquefied natural gas (FLNG) and offshore • Grey and blue H2 • Blue ammonia • Gas-to-liquids (GTL) • Gas Processing & Monetization |

• Biofuels & fuels • Biochemicals • Petrochemicals • Ethylene • Fertilizers • Circular economy |

• Floating offshore wind • Green H2 value chain • CO2 management • Nuclear • Life sciences • Mining & Metals • Aerospace & Defense |

• Genesis - Advisory & digital services • Services to operations: PMC, Cybernetix • Equity linked services • Loading systems |

| One T.EN Delivery | Technology & Innovation |

|

A global delivery organization All operating centers |

Global experts

|

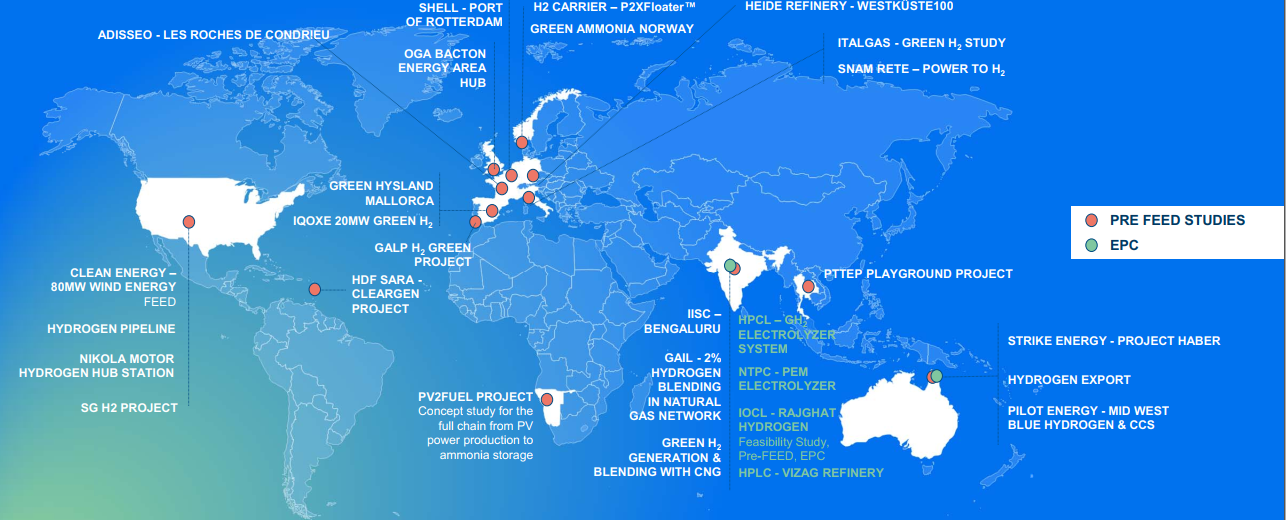

A global footprint

Green Hydrogen Centers of Excellence

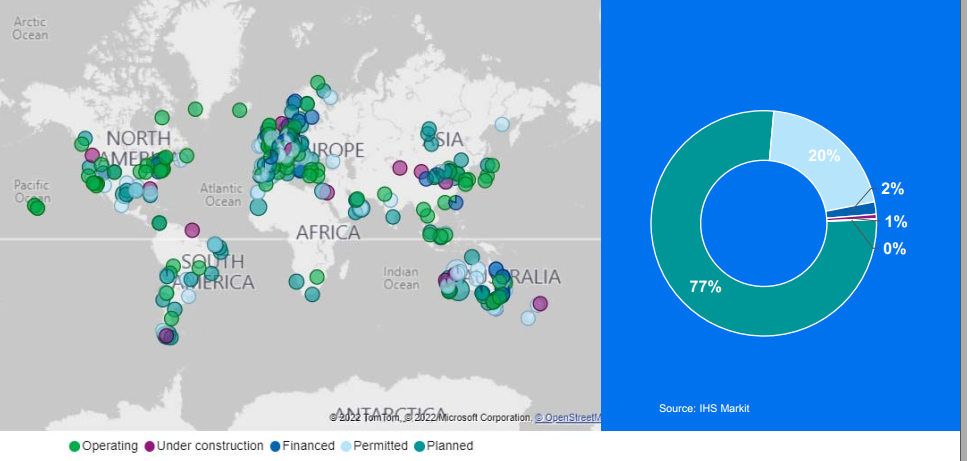

A fast growing market

Global green hydrogen market

|

388 Total capacity (GW) |

639 Number of projects |

0.65 Average project size (GW) |

32,9 Gt CO2 emissions |

~6-8 Gt can be avoided by using hydrogen through fossil fuel replacement (direct or indirect)

Green hydrogen key figures

|

17GW Global electrolysis capacity by 2026 |

57 times the current capacity |

2.5 Bn$ 2025 market value with an annual growth rate of 39.4% |

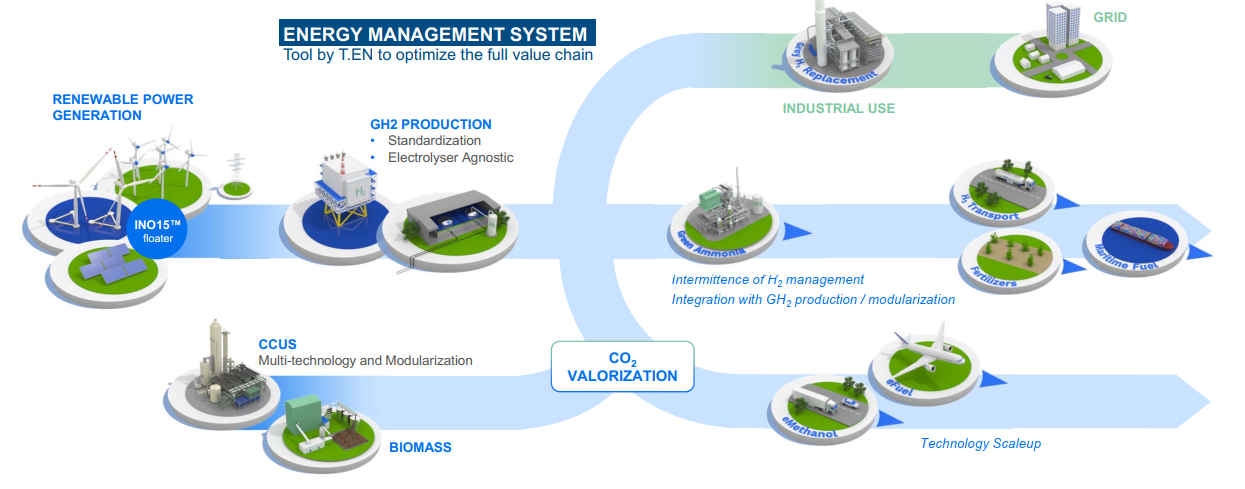

Optimizing the full value chain

From pilot to industrial scale project development

Key points

- Optimized LCOH2 through full chain integration and technology agnostic approach

- End-to-end approach leveraging key skills globally

- Focus on standardization, industrialization and project FID

- Extensive background with complete portfolio of services

Green H2 / Power-to-X

Improving efficiency and affordability by optimizing the entire value chain

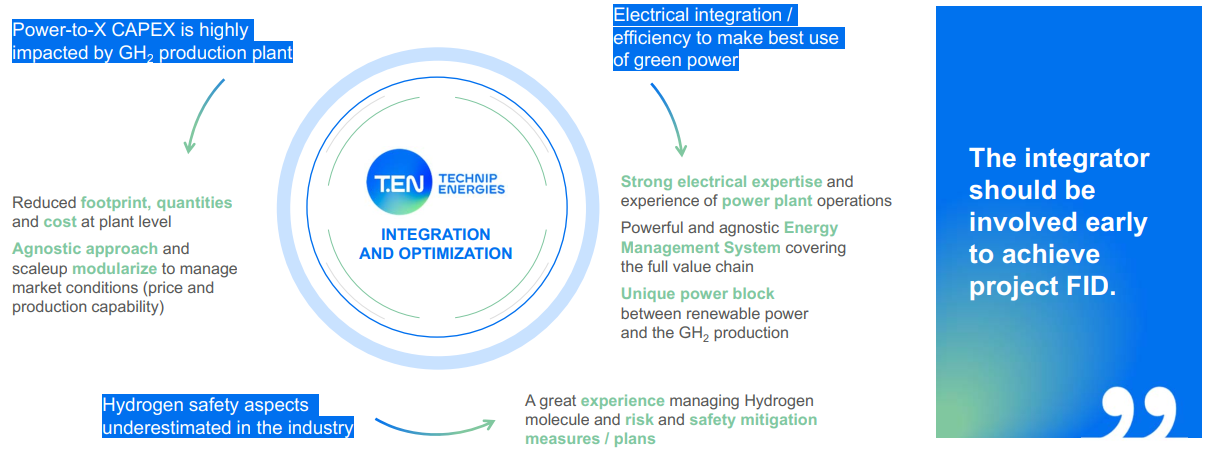

A holistic approach to plant level optimization

Power-to-X chain optimization levers

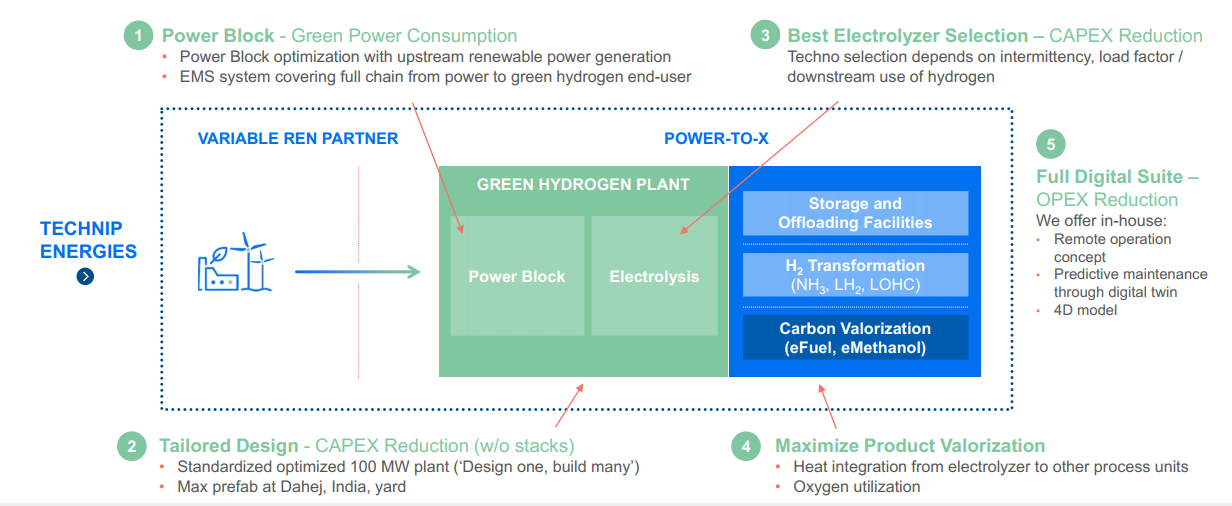

Balancing standardization and tailored design

TECHNIP ENERGIES

|

Power Block

|

1. Power Block - Green Power Consumption • Power Block optimization with upstream renewable power generation • EMS system covering full chain from power to green hydrogen end-user |

|

GREEN HYDROGEN PLANT |

2. Tailored Design - CAPEX Reduction (w/o stacks) • Standardized optimized 100 MW plant (‘Design one, build many’) • Max prefab at Dahej, India, yard |

|

Electrolysis |

3. Best Electrolyzer Selection – CAPEX Reduction Techno selection depends on intermittency, load factor/ downstream use of hydrogen |

|

Storage and Offloading Facilities H2 Transformation (NH3, LH2, LOHC) Storage and Offloading Facilities

|

4. Maximize Product Valorization • Heat integration from electrolyzer to other process units • Oxygen utilization |

|

VARIABLE REN PARTNER POWER-TO-X |

5. Full Digital Suite –OPEX Reduction We offer in-house: • Remote operation concept • Predictive maintenance through digital twin • 4D model |

Our legacy and value proposition

Green hydrogen: Four applications, four markets

|

Large Industry • Refineries • Ammonia • E-fuels / methanol |

Renewable Energy Storage |

Grid Flexibility |

Mobility |

Technip Energies mainly focuses on large-scale industry applications

Remaining unchanged is the electrolyzer package and the ability to integrate in an overall architecture to deliver a turnkey project

A strong heritage

Robust background and in-house skills

| Hydrogen Expertise |

Ammonia and Fuels Expertise |

Electrolysis & Electrical Expertise |

|

275+ H2 references |

50+ References of carbon capture from H2 plants |

20+ Ammonia references under HTAS technology during the past 15 years |

100+ Electrolysis references for electrochemical plant |

| >30% Global installed H2 capacity |

40+ Green H2 references |

30+ Grassroot refineries with capacities up to 400 k BPD |

150 electrical engineers |

3,5 GW of power plants built and operated |

Rising to the challenge as an engineering & technology company

Integrate and optimize bricks at plant level for best LCOH

| Agnostic Technology • Optimize value chain costs • Technology selection • Mitigate upscaling risks |

> Tailor-made Approach at plant level on technology brick level |

Integration / Industrialization • Digitalization • Modularization • Energy Management System (EMS) • Integrated renewable power and green hydrogen |

Green H2 production by water electrolysis

Technology overview

|

Agnostic Approach |

Solutions Overview |

Market Watch |

Best technology choice based on project constraints / economics |

| ALKALINE ELECTROLYSIS |

PEM ELECTROLYSIS |

SOLID OXIDE ELECTROLYSIS |

| • Very mature technology, can operate up to 30 bars • Low compacity compared to PEM due to low energy density • Less reactive than PEM (3 to 5% variation per second for alkaline) • Lowest cost / No rare materials • Stack lifetime: ~ 60,000 – 90,000 hrs |

• Mature technology, can operate up to 30 bars - ongoing development up to 100 bars • High compacity / high-energy density • Highly dynamic (best suited technology for intermittency) • Suitable for offshore application • Higher cost / rare materials • Stack lifetime: ~ 50,000 to 70,000 hrs |

• Technology under development – market entry in ~3-7 years • Best efficiency • High temperature (around 800°C) • Low flexibility (long startup / shutdown times) • No rare materials but top-class metallurgy • Reversible technology, co-electrolysis capability |

Power-to-X key technology factors

Long-standing involvement in the syngas arena

| Ammonia |

Methanol |

X to Liquids |

| • Agreement with the leading licensor including MeOH c-production • 20 ammonia projects in the past 20 years • +350 large fertilizer complexes and integrated units delivered |

• For stand-alone MeOH plant, access to all licensed technologies • Industrial references on base load methanol capacity (5,000 TPD MeOH production) • Ongoing development on e-MeOH solutions as part of carbon capture, utilization & storage |

• Consolidated, ring-fenced alliance with a leading GtL licensor • Development of unique GtL assets (such as Oryx GtL in Qatar) • Exclusive codevelopment of Fischer-Tropsch reactor through decades of joint technology development |

Optimizing LCOH

Through industrialization and cutting-edge digital solutions

Industrialization and scaleup

Readiness for gigawatt scale plants

|

Key aspects: • Technology driven, agnostic

Design one, build many:

|

LARGE GREEN H2 BLUEPRINT BUILDING

BUILDING

LARGE GREEN H2 BLUEPRINT BUILDING

Utilities EMS by T.EN Digital Twin by T.EN = VERY LARGE GREEN H2 PLANT |

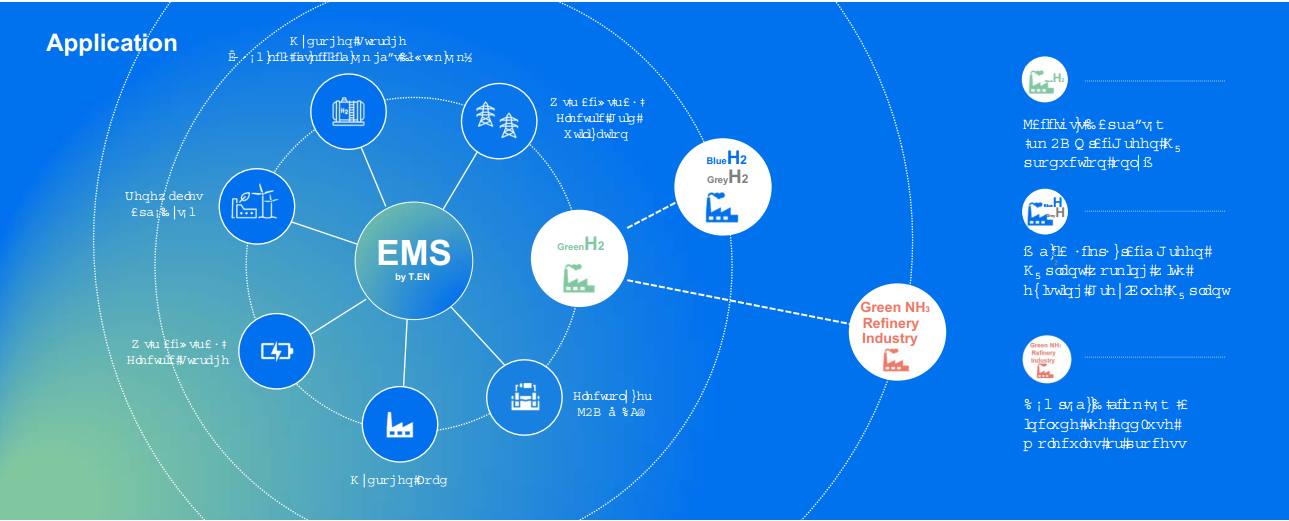

Our EMS* by T.EN solution for green H2

Adding value with EMS by T.EN

|

INCREASED ELECTROLYZER LOAD FACTOR Lower LCOH, Higher NPV

DYNAMIC OPTIMIZATION Possibility to include sliding windows constraints (e.g. max CO2 content over a period of time) FINANCIAL GAINS Lower LCOH, higher NPV thanks to realtime arbitration of electricity and other INCREASED H2 RATIO In case of a brownfield mix between blue or grey H2 with green H2 LOWER CO2 FOOTPRINT

Higher controllability for CO2 content of green H2

|

EMS by T.EN EMS* by T.EN and Model Predictive Control

• Real-time optimized system in operation Compared to a “Logic Rules EMS,” EMS by T.EN Enhanced Return On Investment |

Improving total cost of ownership

|

Price Breakdown |

OPTIMIZING BRICKS AT PLANT LEVEL |

|

|

8% 17% 8% 67% |

• All parameters are considered including renewable power generation, quantities, production • Technology agnostic approach with screening, selection and licensor management • Energy Management System provides full architecture integration from renewable production to hydrogen monetization • Multidiscipline engineering competencies to verify, support and industrialize OEM solutions • Project development support to secure FID with permitting, financing, business models, production of electrolysers • Legacy of hydrogen experience with 275+ plants worldwide, electrolysis, ammonia / methanol |

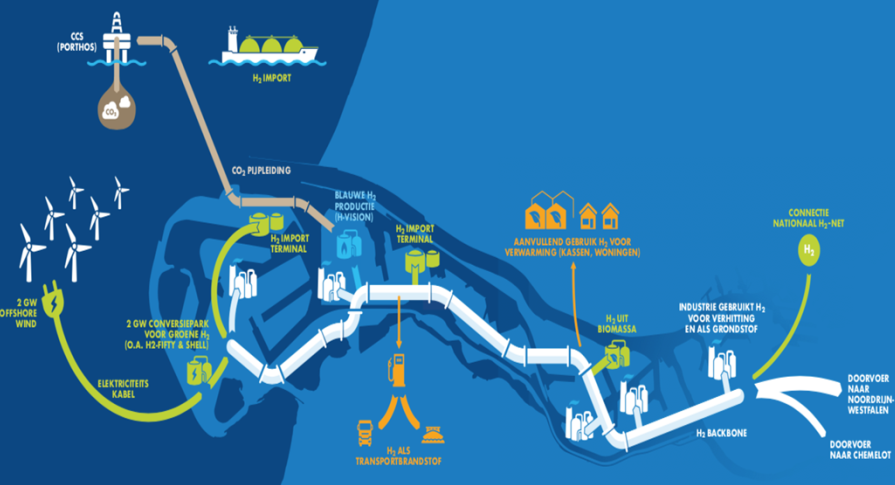

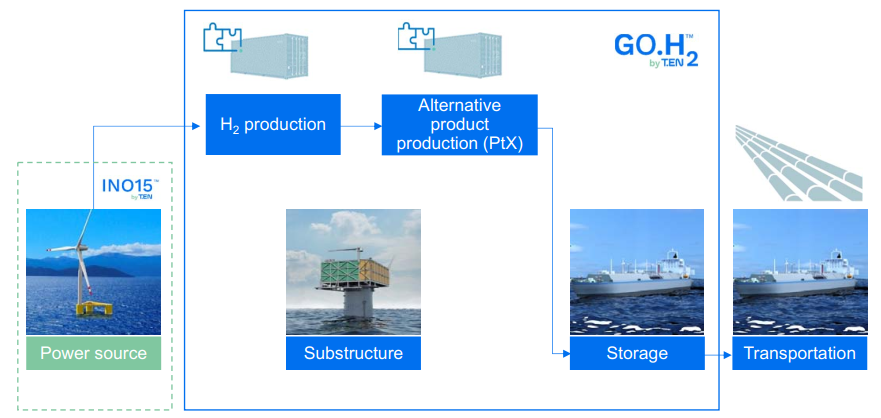

Offshore green hydrogen production

Integrated Offshore Renewable Power and Green Hydrogen Production

• Complementing our floating offshore wind solutions – INO15™

• GO.H2 by T.EN is a suite of offshore solutions to address various asset needs

• Intermittency in operations optimized through EMS

> Flexible solutions tailored to meet client needs!

The GO.H2 value chain

|

ADJUSTABLE BUILDING

•Substructures |

|

> A full suite of solutions for green offshore hydrogen production

target capacities

| 15 MW on floating offshore wind turbine foundation and pilots / battery function or H2 fuel to end-user |

50 MW Battery function or H2 fuel to end-use |

> 200 MW H2 or P2X for export to general market |

Basic Units P2X Add-ons

|

| H2 Platform |

H2 Platform |

NH3 / LOHC Platform |

H2 Power Platform |

H2 Power Platform | |

| Function | Fuel production |

Fuel production |

Fuel production |

Battery function |

Battery function |

| H2 Carrier |

H2 production |

H2 production |

+NH3/LOHC production |

+Electricity production |

+Electricity production |

| Substructure |

Fixed: jackup / jacket floating: ship shape |

Floating: ppar/ semisub/ cylindrical/TLP |

Fixed/floating |

Fixed/floating |

Offshore wind floater/substation floater |

| Transportation |

Transport pipe |

Transport pipe/tanker |

Transport pipe/tanker |

Cable |

Cable |

| Location |

Near shore benign water |

Deep water, harsh environment |

Near shore/ deep water |

Close to user |

Close to user |

> Flexible solutions tailored to meet client needs

Green H2 references

Zoom 200MW hydrogen plant

Produce carbon-free hydrogen at scale from renewable power

- Objective: Produce carbon-free hydrogen at scale from renewable power in the Port of Rotterdam, replacing existing grey hydrogen

- Our scope: FEED competition to deliver cost-competitive and highefficiency solutions

• Upscaling green hydrogen solutions beyond existing references

• High-efficiency solution throughout plant life

• High availability and reliability in the context of intermittency

• Optimized TCO

• Single-point systems integrator

• Modularization approach

• Carbon-free hydrogen facility

• Contract: FEED

• Client: Confidential

• Location: The Netherlands

Zoom Clear Creek green H2 project

Large-scale green hydrogen production and distribution

- Objective: Create a complete H2 infrastructure based on 240/600MW of renewable wind power

- Scope: Define the full project scope, identify best available technologies and provide pre-FEED, FEED and EPC services

• Phase 1 will create 15MM SCFD of green H2

• Phase 2 will produce up to 40MM SCFD

• Design to include production, storage and distribution of green H2

• H2 to be used for export, industrial and mobility applications

Provide full scope of engineering services from feasibility study to EPC

• Contract: Consultancy to full EPC

• Client: Clean Energy Holdings

• Location: Colorado, USA

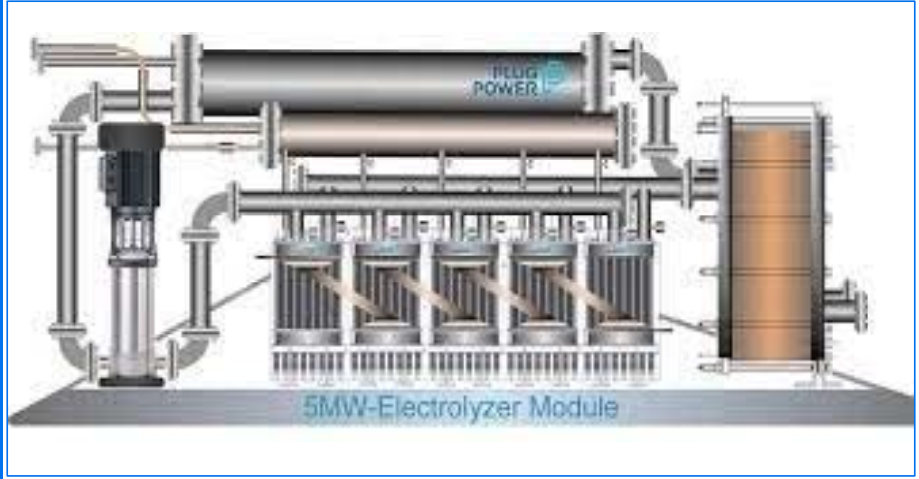

Zoom NTPC 5 MW PEM based H2 unit - EPCC

India’s first 5 MW pilot PEM unit for NTPC

- Objective: Produce carbon-free hydrogen at a pilot scale at the NTPC Vindhyachal Power Plant with an ultimate aim to pilot a green methanol facility

- Scope: Technology supply through partner + EPCCC on an LSTK basis

• 2 tons per day of PEM electrolyzer based hydrogen production

• Electrolyzer stacks from technology partner

• T.EN India capable of complete design / engineering of balance of plant and system integration

Largest PEM based H2 EPCC awarded in India

• Single-point systems integrator

• Modularization approach

• Carbon-free hydrogen facility (based on power source)

• Contract: EPCC

• Client: NTPC

• Location: India

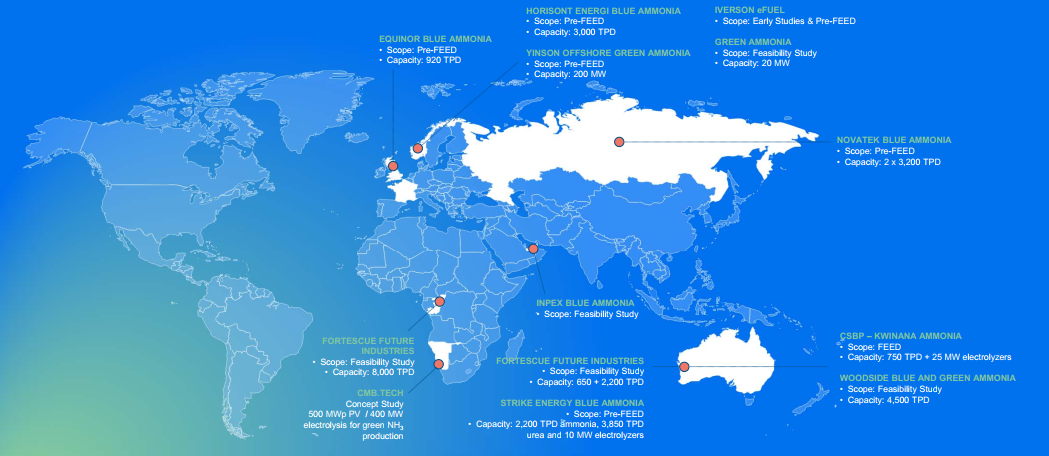

Green and blue NH3 references

Zoom H2 integrated study

Comparison of H2 transport vectors (NH3, LH2, MCH & LOHC)

- Objective: Develop concepts for different H2 transport vectors and different production capacities ranging from 10,000 TPY to 300,000 TPY H2 production capacity

- Scope: Develop technically and economically feasible concepts for 30 different cases; Develop AACE Class 4/5 CAPEX cost estimates,, layout, overall mat. balance, OPEX, utilities cons., etc.

Investigated:

• Blue / green hydrogen production comparison

• Integration of blue & green hydrogen

• Economical comparison of NH3, LH2, MCH & LOHC concepts including Levelized cost for each concept

• TRL assessments / Potential optimizations identifications

• Contract: Feasibility Study

• Client: Woodside

• Location: Western Australia

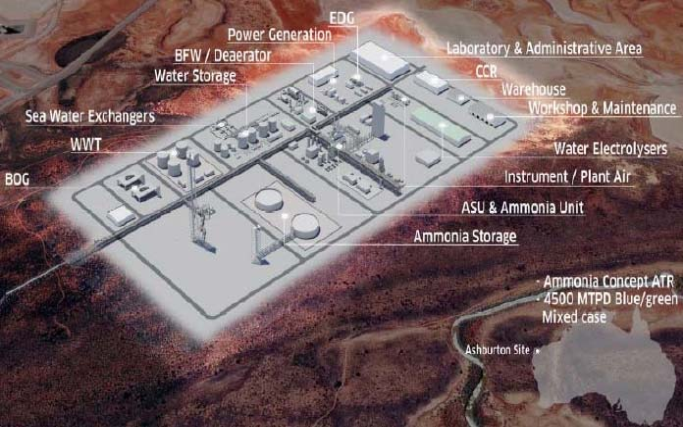

Zoom 3GW feasibility study

World’s largest hydroelectric project to produce green ammonia

- Objective: Develop concepts of ammonia FPSO for ammonia production of 650TPD and 2200TPD and compare to a concept of a land-based plant

- Scope: Develop technically and economically feasible concepts of the plant and Class 5 CAPEX cost estimatesDeliver building block study to compare limitations, advantages and disadvantages of each concept .

Three design concepts investigated:

• 300MW electrolysers + ammonia + storage on single FPSO

• 1GW electrolysers + ammonia module + storage on single FPSO

• 1GW electrolysers (onshore or offshore separate from ammonia production) + ammonia and storage on FPSO

• Contract: ConceptSelection Study

• Client: Fortescue Future Industries

• Location: Australia Northwest nearshore, aspiration to locate worldwide

KEY CHARACTERISTICS OF FLOATING PLANTS:

| 650TPD of ammonia | 2,200TPD of ammonia | |

| Electrolysers | 60 x 5MW | 200 x 5MW |

| Total electrolyser power | 300MW | 1GW |

| Power from onshore grid | 20MW | 60MW |

| Ammonia substructure storage | 54,000m³ | 59,000m³ |

| Vessel dimensions | 250m x 60m | 420m x 70m |

Zoom 500 MWp green NH3 Pre-FEED

Green ammonia production from solar farm

- Objective: Develop a green ammonia plant based on 500 MWp solar farm including 400 MW electrolyser capacity, H₂ pipeline, ammonia synthesis and utilities and offsites.

- Scope: Run the technical and economic assessment of the plant; provide Energy Management System and optimization of the entire plant from PV to NH3 offloading; develop plot plan, AACE Class 4 CAPEX and OPEX

• 500 MWp solar panels to be installed in desert area

• 400 MW pressurised alkaline based electrolyser package

• 50 kms H2 pipeline used as intermediate storage

• Ammonia synthesis trains installed near shore

• Utilities and offsites design

• Ammonia storage, boil-off handling and offloading

• Levelized cost of ammonia optimization

• Contract: Pre-FEED

• Client: CMB.TECH

• Location: Namibia, Africa

Zoom 300MW green ammonia Pre-FEED

Green ammonia production from hydropower

- Objective: Develop a green ammonia plant based on 300 MW hydropower including 280 MW electrolyser capacity, ammonia synthesis and utilities and offsites

- Scope: Run the technical and economic assessment of the plant; provide optimization of the entire plant from electrical substation to NH3 offloading; erform OEM evaluation; perform NH3 pipeline routing selection; develop plot plan, AACE Class 4 CAPEX and OPEX; provide client assistance for permitting and other third-party activities

• 300 MW hydropower

• 280 MW electrolyser package

• 600 TPD ammonia synthesis train

• NH3 pipeline from ammonia synthesis to storage

• Utilities and offsites design

• Ammonia storage, boil-off handling and offloading

• Levelized cost of ammonia optimization

“Technip Energies has been selected by IVERSON eFuels AS, a special purpose vehicle between CIP, Hy2gen and Trafigura, to perform the engineering design of a complete gre

• Contract: Pre-FEED

• Client: Iverson eFuels AS

• Location: Norway

Why Technip Energies?

- A leading player in the hydrogen and derivatives market with 50+ years experience

- A safety expert

- A long history of integrating technologies from third parties and scaleup

- A strong electrical expertise with 50+ specialists and 500+ MW of power plant built and operated

- A reliable and recognized partner with financial strength and global coverage