Overview of KGS's Hydrogen Safety System: From Production to Utilization

January 9, 2026, by HeeJung Kim from UNIHYS

The Hydrogen Safety Technology Institute of the Korea Gas Safety Corporation (KGS) plays a crucial role in establishing and maintaining safety standards and management systems throughout the entire hydrogen value chain. By integrating international standards (from the US, Japan, EU) with domestic conditions, KGS has developed a comprehensive safety management framework for the nascent yet high-potential hydrogen industry.

1. Hydrogen Value Chain and Safety Management

KGS categorizes and manages safety across four main stages of the value chain:

a) Hydrogen Production

-

Production Methods: By-product hydrogen, Extraction, Water Electrolysis.

-

Safety Standards: Application of the High-Pressure Gas Act for by-product hydrogen facilities; manufacturing & installation standards for extraction equipment and production facilities.

-

Management System:

-

Construction Stage: Technical review + completion inspection.

-

Operation Stage: Assignment of safety manager; regular diagnosis (annual); real-time monitoring; product and sample inspections.

-

b) Hydrogen Transportation

-

Vehicle: Use of tube trailers.

-

Safety Standards: Standards for storage containers, connection tubes, collision prevention frames.

-

Management System: Transportation vehicle registration system; vehicle location tracking management system; completion inspection; arrangement of management staff; precision diagnosis system.

c) Hydrogen Storage

-

Purpose: For refueling use.

-

Safety Standards: Storage tank standards per the High-Pressure Gas Act; securing separation distance; installation of safety devices; manufacturing and internal management standards for crack prevention.

-

Management System:

-

Manufacturing Stage: Factory inspection (full inspection); technical review & completion inspection.

-

Operation Stage: Resident safety manager; regular diagnosis (annual); double inspection system.

-

d) Hydrogen Utilization

-

Applications: Refueling stations (≥700 bar), Fuel cells, Industrial use (120 bar).

-

Management System:

-

Refueling Station: Use of certified products; safety evaluation; annual precision diagnosis; quarterly quality management.

-

Fuel Cells: Product inspection; completion and regular inspection.

-

Industrial Use: Resident safety supervisor; legal inspection.

-

2. Overview of Hydrogen Vehicle Refueling Stations

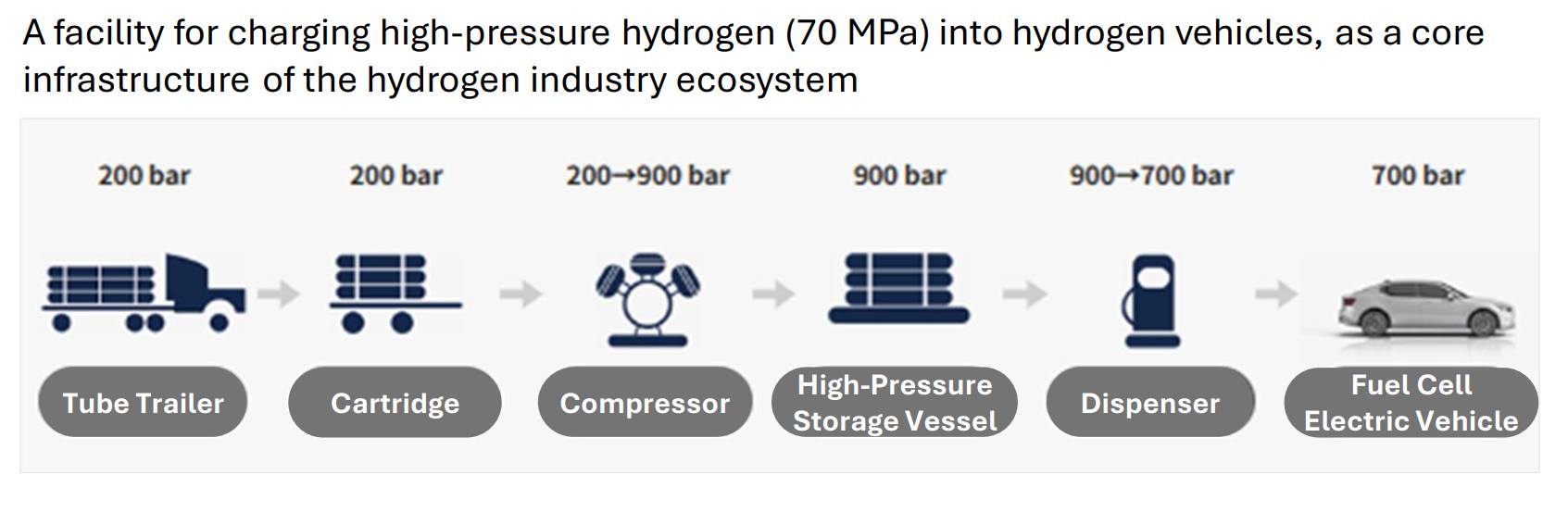

High-pressure hydrogen refueling stations (70 MPa) are core infrastructure of the hydrogen industry ecosystem.

Basic Refueling Process:

Transport via Tube Trailer (200 bar) → Compression (Compressor, up to 900 bar) → High-Pressure Storage Vessel → Dispensing via Dispenser (down to 700 bar) → Refueling of Fuel Cell Electric Vehicles (FCEV).

Classification by Supply Method:

-

Storage-based (Off-site) Station: Hydrogen is produced centrally and transported to the station via tube trailer.

-

Production-based (On-site) Station: Hydrogen is produced directly at the station from natural gas (via SMR) or water electrolysis using renewable energy.

Classification by Deployment Method:

-

Integrated Type: Operated jointly with gasoline, LPG, or CNG stations.

-

Standalone Type: Operated exclusively as a hydrogen refueling station.

3. Hydrogen Production Facilities: Water Electrolysis & Extraction

Water Electrolysis System:

-

Principle: Uses electricity (from thermal, solar, wind power, etc.) to decompose water (H₂O) into Hydrogen and Oxygen.

-

Application: Supplies hydrogen for fuel cells (residential, commercial) and industrial sectors (semiconductors, metal processing, etc.).

Hydrogen Extractor:

-

Principle: Decomposes natural gas, LPG, etc., at high temperature (~800°C) to produce Hydrogen and Carbon Dioxide.

-

Application: Similar to electrolysis-derived hydrogen, used for fuel cells and industrial applications.

4. Key Programs of the Institute

The Hydrogen Safety Technology Institute implements several core programs to support the industry:

-

Hydrogen Refueling Station Safety Support

-

Hydrogen Equipment Inspection

-

Hydrogen Safety Management Policy Development

-

New Hydrogen Technology Safety Management Support

-

Hydrogen Sector Education and Training

-

Hydrogen Safety Culture Promotion

-

Operation of the Hydrogen Product Testing and Evaluation Center

Conclusion: With a systematic, cradle-to-grave approach, KGS is establishing a robust safety foundation for South Korea's hydrogen industry. The combination of standardization, rigorous oversight at every stage, and comprehensive support programs not only ensures safety but also promotes the sustainable development of and trust in hydrogen energy for the future.