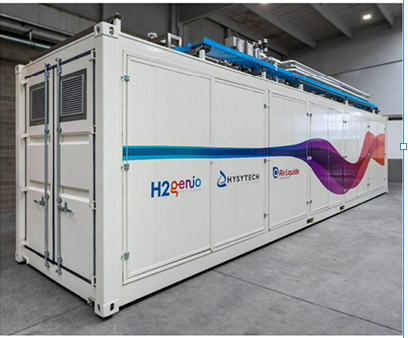

Product Main Features

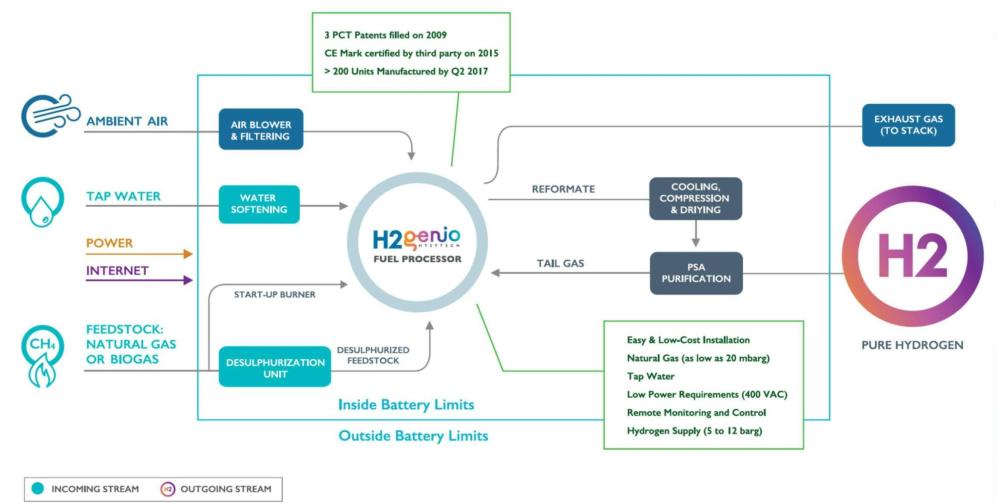

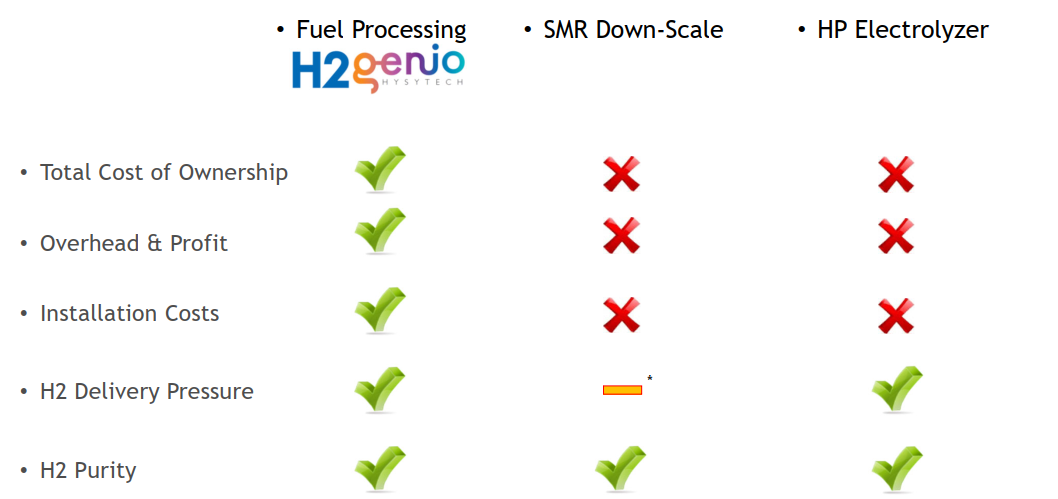

- Hysytech’s steam reforming technology is used to produce high-purity hydrogen

- uses Natural Gas or Biogas

- Very low electrical requirements

- Minimal installation and very low operating costs compared to electrolyzers

- Multiple modules can be installed in parallel to achieve higher capacities

Specifications

| Hydrogen purity: |

Standard design for 99,99% ‐ 99,9999% (grade 4.0 ‐ 6.0) Other upon request |

| Hydrogen Delivery Pressure: |

Standard design 5‐12 barg. Others upon request |

| Natural Gas Supply Pressure: |

Standard design 0,020 ‐ 0,500 mbarg. Others upon request |

Market Potential

Industrial & Manufacturing Sector (both mature & Innovative sectors):

|

Applications with flow rates and users that are:

|

Hydrogen as fuel: demand for Hydrogen Refueling Stations:

> 50 plants installed & operating in USA;

> 80 plants installed & operating in EU by Q2 2016;

> 500 plants planned (EU + USA + ASIA), (>400 EU only).

Who needs it?

- • End-User: Client who currently buys or intends to buy Hydrogen from an Industrial Gas Company (i.e. Air Liquide, Nippon Gases, Praxair, Linde, Messer, Air Products, etc.).

- Typical End-User is a company from mid-light industrial or manufacturing sector

- (i.e. electronics, metals, glass, chemicals, food, etc.). Increasing interest on H2 Refueling Stations.

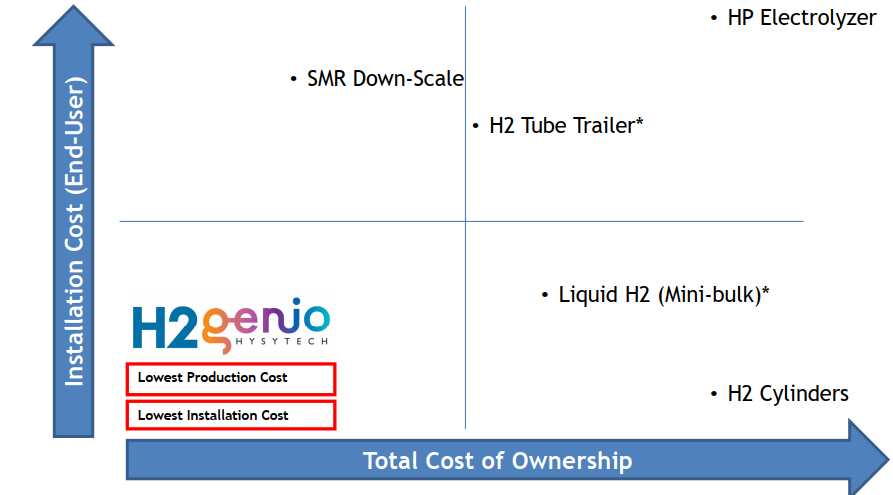

- State-of-the-art: Industrial Gases Company delivers Hydrogen as:

- Gas Cylinders: 1 cylinder is 80 liters (12,8 Nm3@160 bar), 16-cylinder pack (200 Nm3)

- Liquid Mini-Bulks: 1 bulk is 450 – 3.000 liters (typical flow rates from 15 – 60 Nm3/h)

- Gas Tube Trailers: 1 trailer is approx. 4.500 Nm3 (EU)

Delivery Entry Barriers = On-Site

Space Constrains & Regulations:

EU regulations regarding flammable gases storage is quite stringent. Maximum allowable quantities as well as minimum space or distances often make the use of Mini-Bulk or Tube Trailers impossible. Furthermore, the permitting process is usually long and uncertain.

End-User Installation Cost:

Client is often reluctant to expend money on fixed assets related to gas supply. “Installation Cost”, as intended here, does not include the “Equipment Cost”, it means the cost the Client has to bear to host the on-site equipment only (i.e. upgrading works, hook-up works, etc.). “Equipment Cost” is included on the “Gas Supply Agreement” as a monthly fee or built-in on the Hydrogen price (see CAPEX section).

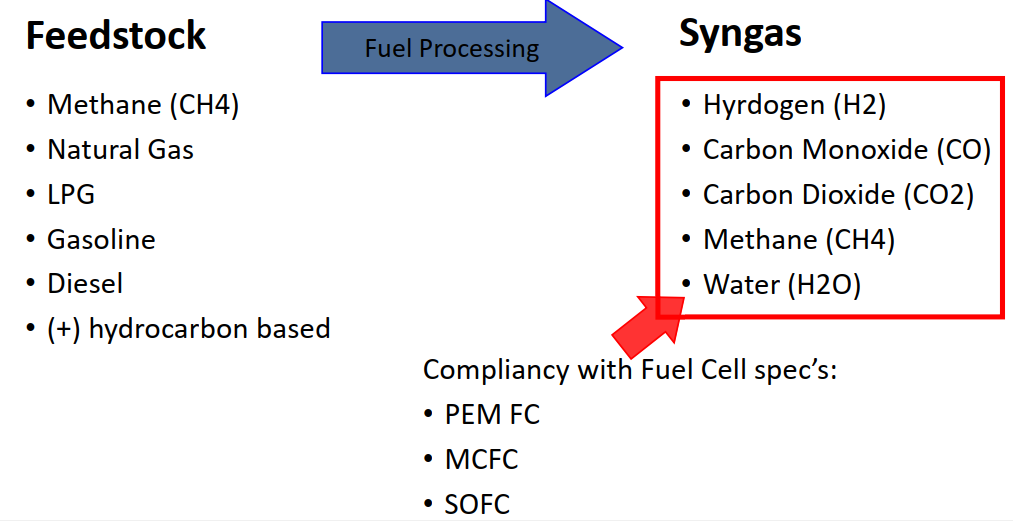

Fuel Processing Technology (Specs)

Fuel Processing Technology and Product Advantage

|

1. High Fuel Processing Efficiency; 2. Uses Natural Gas low pressure; 3. Tail‐gas Afterburner; 4. Start‐up Burner function included; 5. Quick Warm‐up function 6. Burner exhaust complies with EU regulations. 7. Regulatory Framework 8. IP 9. Reliability

10. Low Manufacturing Cost |

Up to 97% (including Burner, excluding elect. BoP) No electric self‐consumption for gas compressionSafety and Heat Recovery for lower fuel consumption No additional buner or heating device is required System up and running in few minutes time Low‐CO, Low‐NOx CE Compliance for Fuel Processor design and control logics Process, Know‐how & 3 PCT Patents Designed for Uptime >8.000 h/y; Sizes already industrialized, no expensive catalyst is used |

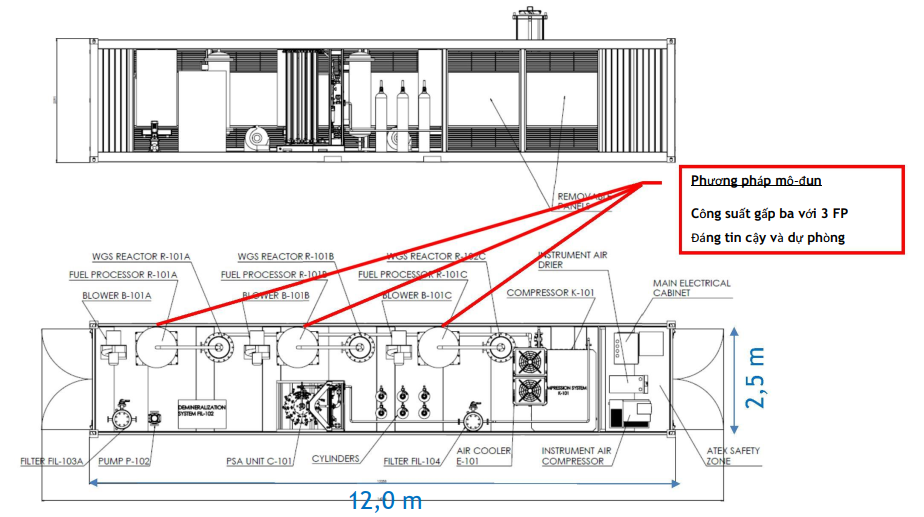

Fuel Processing Technology Scale‐Up and Reliability

1. 3 Standard «System» Sizes: 30, 60, 100 Nm3/h of H2;

2. 1 Standard «FP» Design: 35 Nm3/h of H2;

i. 30 Nm3/h of H2 = 1 FP;

ii. 60 Nm3/h of H2 = 2 FP;

iii. 100 Nm3/h of H2 = 3 FP;

3. Only 1 Manufacturing Process optimized for 1 FP Design (Lean & High Quality);

4. Adopting 1 single standard FP design allows a very efficient spare stock and fast maintenance service;

5. Downtime will be minimize thanks to back‐up FP units already available at our workshop (any FP will fit to any System or installation. 1 full replacement turnaround in less than 1 shift);

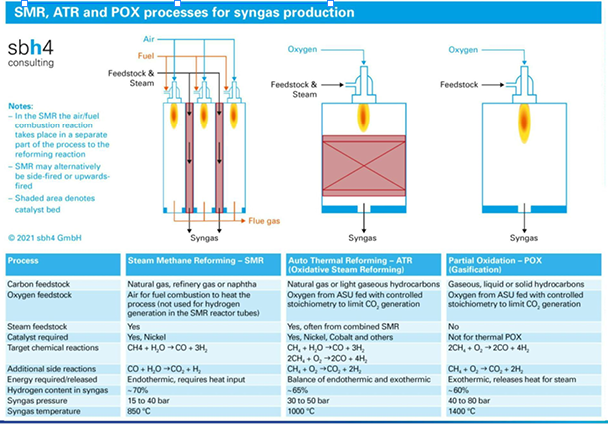

Process Based on SMR + WGS

Turn-key Product Battery Limits

Hight Purity Hydrogen for Steel Industry (120 Nm3/h)

Features:

|

• High Purity Hydrogen >99,995%vol • Capacity up to 120 Nm3/h • Power Consumption <40 kW • Delivery Pressure 11 barg • Natural Gas feed: • Pressure <0,350 mbarg • Odorized Gas • Fully automatic & unmanned

|

|

Hight Purity Hydrogen for Fuel Cell (40 Nm3/h)

Features:

|

• High Purity Hydrogen >99,9999%vol

• Capacity up to 40 Nm3/h • Power Consumption <18 kW • Delivery Pressure 6 barg • Natural Gas feed: • Pressure <0,020 mbarg • Odorized Gas • Fully automatic & unmanned

|

|

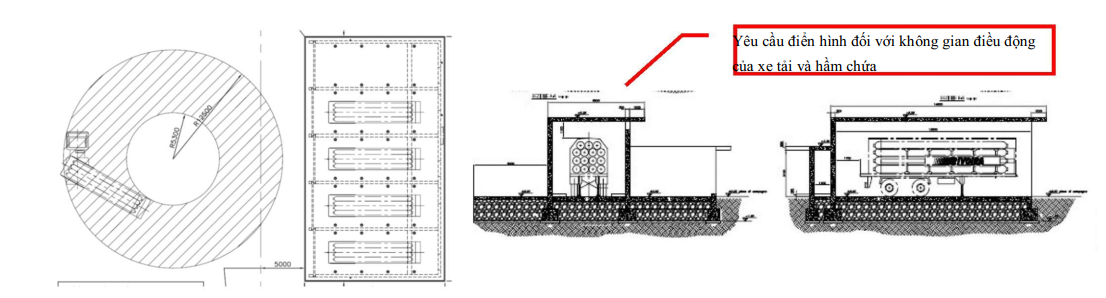

Fuel Processing Technology (120 Nm3/h Layout)

Known Competitors & Alternatives

* Permitting (safety and regulatory) and/or space constrains often make this kind of delivery not possible

Economics Comparison

* suitable gas network must be available nearby