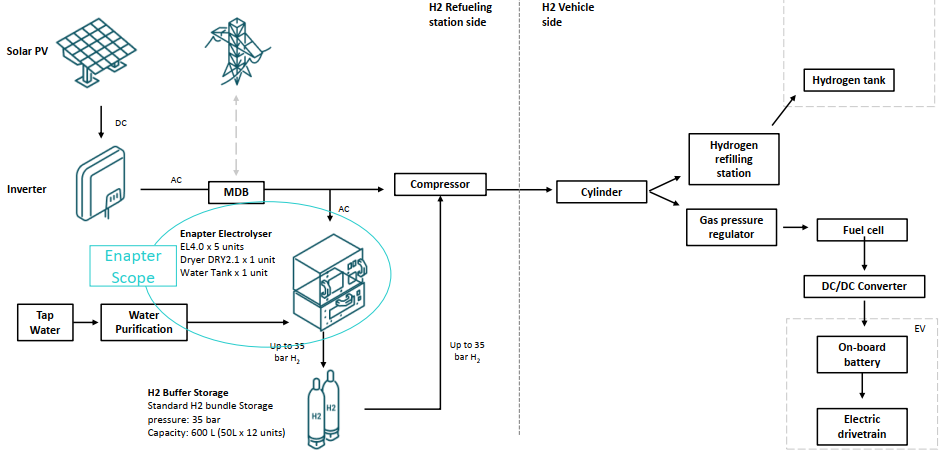

Hydrogen Refueling Station

Overview

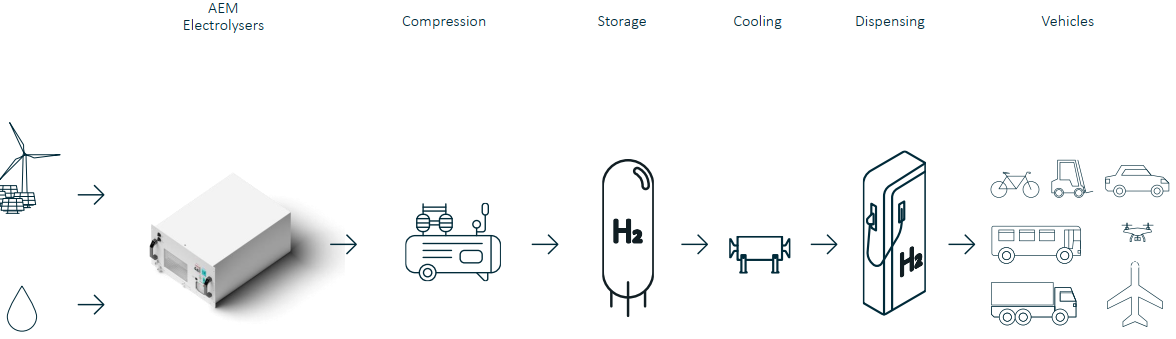

Hydrogen refueling stations gather the infrastructures needed to refill fuel-cell vehicles with hydrogen.

- They include hydrogen supply (e.g. onsite production), compression, storage, cooling and dispensing.

DESIGN OPTIONS

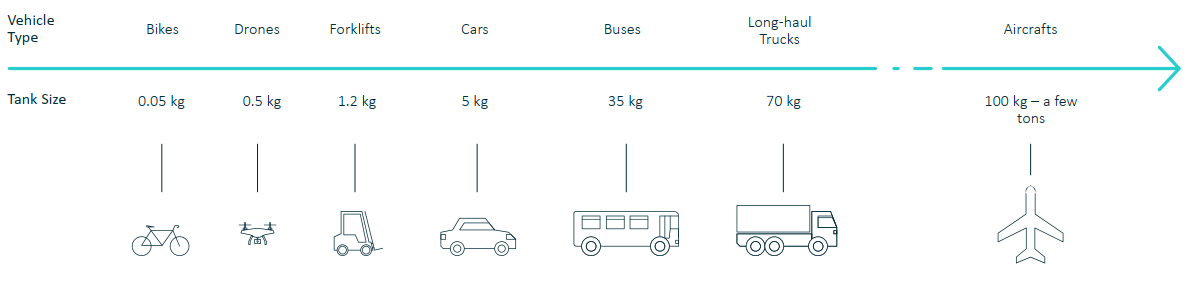

- Type of vehicles to refill: bikes, drones, forklifts, cars, buses, trucks, aircrafts etc.

- Refilling pressure: 350 and/or 700 bar

- Refilling speed: fast (a few minutes) or slow (up to hours)

- Hydrogen output capacity: max. # of fillings per day

- Dispensing capacities: simultaneous fillings, back-toback capacity

Disclaimer

|

|

Hydrogen Vehicles

General Overview of Components

H 2 R e f u e l l i n g – F C v e h i c l e

Schematics – 1 Stage Storage

Enapter Scope

| Unit | Number of units | Flow | Daily production capacity (24 hours) | Function | Data sheet | User manuals |

| Electrolyte unit EL4.0 | 5 | 2.5Nm3/hr | 5kg/day | Hydrogen production | www.enapter.com/el40 | www.enapter.com/el40_manual |

| Dryer 2.1 | first | 2.5Nm3/hr | Increase the purity of hydrogen from 99.9% to 99.999% by steam drying to less than 5ppm. | www.enapter.com/dry21 | ww.enapter.com/dry21_manual | |

| Water tank WT2.1 | first | 3.8L/min | Store 38.5l of purified water and check the quality to protect the electrolyzer from unsuitable water. | www.enapter.com/wt21 | www.enapter.com/wt21_manual |

Multi-talents Enapter devices

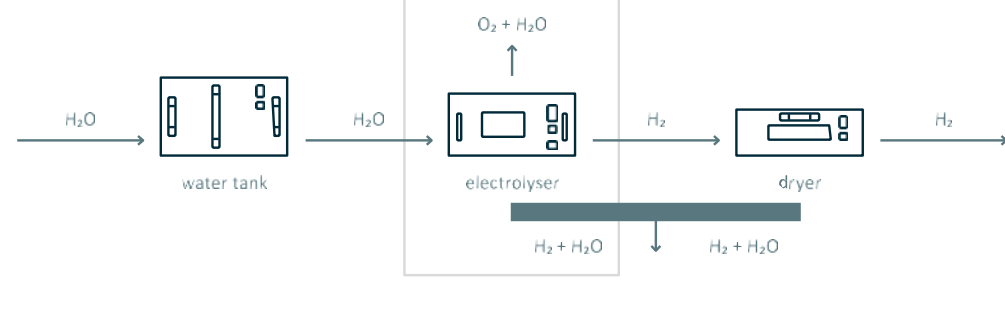

How it works?

Enapter’s patented anion exchange membrane (AEM) electrolyser is a standardised, stackable and flexible system to produce on-site hydrogen. The modular design – paired with advanced software integration – allows set up in minutes and remote control and management. Stack this electrolyser to achieve the required hydrogen flowrate.

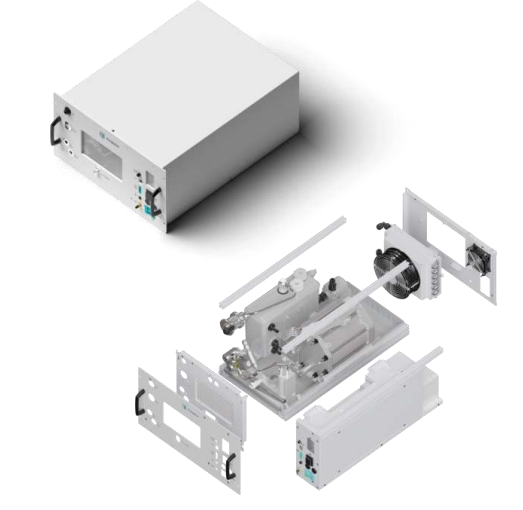

Single-core electrolyser series

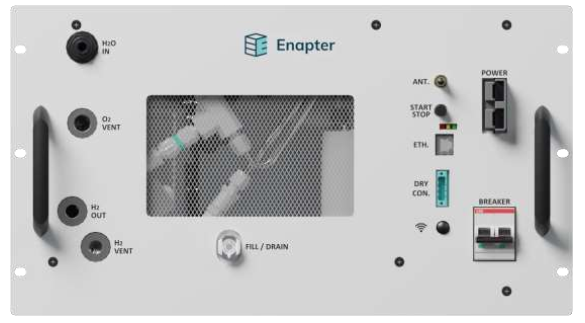

The Electrolyser EL 4.0

- Hydrogen Production: 500 NL/hr or 0.5 Nm³/hr

- Power Consumption: 2.4 kW

- Efficiency: 4.8 kWh/Nm³

- Hydrogen Purity: 99.9% or 99.999% (with optional dryer)

- Water Input Conductivity: <20 μS/cm

- Output Pressure: 35 bar

Datasheets:

EL 4.0 AC (Air cooled / Liquid cooled)

EL 4.0 DC (Air cooled / Liquid cooled)

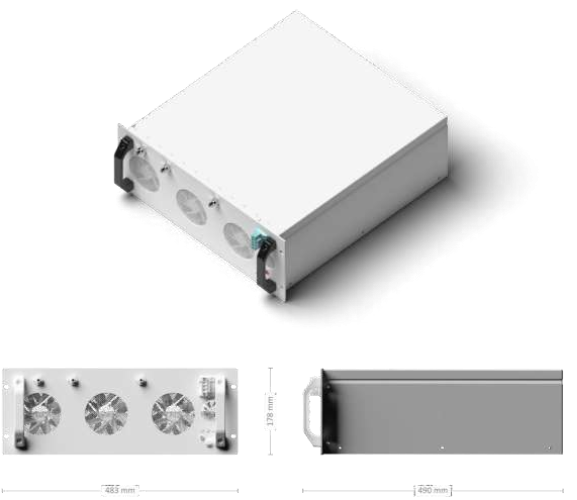

DRYER

Dry Index 2.1

Hydrogen flow rate at 35 bar

up to 2.5 m3/hr

Hydrogen output purity

>99.999%

Dewpoint (after drying)

-70 °C

Power consumption

200 W (operative)

10 W (standby)

Power supply

AC 200-240 Vac,

50/60 Hz

One to five

Up to 5 AEM electrolysers can be

connected to the DRY 2.1

WATER TANK

The WT 2.1

Capacity

38.5 L

Water input pressure requirement

0-6 barg

Maximum power consumption

35W

Power supply

AC 110-240 Vac,

50/60 Hz

Recommended AEM electrolysers to

be supplied

11

ONSI TE REFUELING

H2 Mobility Solutions

In 2021, Fuel Cell Systems developed a combined hydrogen refueling and heating system in Wales, as part of the MHEK project.

- The “Milford Haven: Energy Kingdom” project wants to demonstrate the practical application of hydrogen technology

- It features a refueling station integrating 2 Enapter electrolysers, for hydrogen-powered cars from the company Riversimple.

- A hydrogen-ready smart hybrid heating system has also been installed and is being tested in an operational Port building.

ONSI TE REFUELING

H2 Mobility Solutions

Hydrogen vehicles are quickly gaining ground around the globe

- On-site refueling for fuel cell drones, cars, planes or other vehicles is another use case for decentralized hydrogen production.

- Enapter is working with Hyperion Motors to supply the Hypercar with the clean fuel it needs for power.

- The HyFlyer project aims to decarbonise medium range passenger aircrafts using hydrogen.

ONSI TE REFUELING

H2 Mobility Solutions

Hydrogen vehicles are quickly gaining ground around the globe.

- Narwhal 2” is a fuel cell drone that can carry up to 1kg of equipment

- It is mainly used for surveillance and can fly for 2 hours while transmitting video up to 30 km away.

- B-Shark also designed a mobile refueling station that integrates an Enapter electrolyser. Rather than buying large amounts of hydrogen and purchasing an additional compressor, generating hydrogen with our AEM electrolyser enabled the commercialisation of the drone.