Multinational technology company Wilo created the H2Powerplant system — along with French electrical engineering company Schneider Electric — initially to provide the Wilopark headquarters and plant with emergency backup power using green hydrogen. However, it is intended as the basis for a self-sufficient, decentralized and renewable energy supply network – and is designed to expand the potential to allow for self-sufficient energy supply for up to two days.

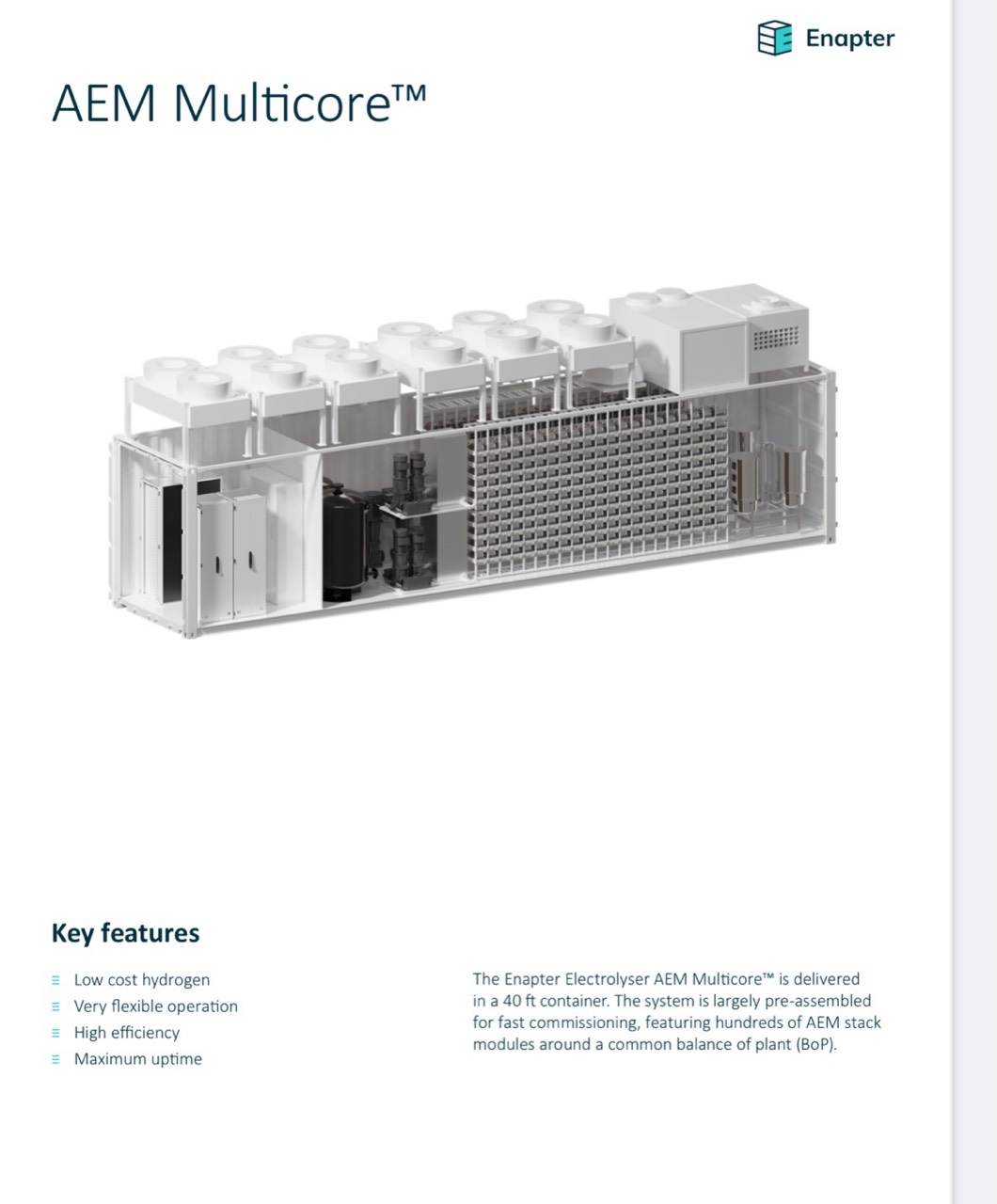

Wilo's H2 Power Plant has four core components, of which the first component is the Smart Factory's rooftop photovoltaic system and the second component is the cluster of 96 AEM Electrolyzers supplied by Enapter that use PV electricity to generate green hydrogen. With its 29.8-meter-long hydrogen storage tank, Wilo can achieve short- to long-term energy storage, then convert hydrogen into electricity as needed using fuel cells supplied by Proton Motor. In this way, the modular system will generate up to 10 tons of green hydrogen per year, and the waste heat from the electrolysis process can also be used directly on-site in the interconnected system or converted into a cooling system.

Electrolyzer (single core AEM) 96 x EL 2.1

Container H2 520 kg

Photovoltaic (PV) 3 MWp

76.5 kW fuel cell

100 kWh and 62.5 kWh feet

Dryer 19 x DRY 2.1

Enapter EMS Toolkit Energy Management System

Active since 2022

AUTHOR IS Dr. ERIC NGUYEN, IBAS